Wet Rod Mill

444A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill, wet rod mill. Different from the ball mill is built-in rod mill is a steel rod type grinding body, the use of cy...

View detailsSearch the whole station Hot Product Catalog

The current sand and gravel market faces high demand but limited natural sand resources and rising prices. Conventional sand-making production lines suffer from low output and inconsistent quality. When searching for “clinker sand-making plants,” you likely seek more than just equipment specifications—you need proven solutions that deliver stable, high-quality manufactured sand and reliable returns.

With numerous suppliers competing for your business, how can you ensure your chosen production line excels in energy efficiency, environmental compliance, sand yield, and long-term operational costs? This article provides an in-depth analysis of how to configure and optimize a high-efficiency 100-ton-per-day production line for maximum output.

(一) Production Capacity Analysis

With the continuous growth in global demand for compact sand-making production lines and increasingly stringent restrictions on river sand mining, the market for manufactured sand is rapidly expanding. Particularly for 100-ton-per-day production lines (equivalent to 12-15 tons per hour), their low investment threshold, short construction cycle, and strong adaptability make them ideal for small-scale construction projects. For rural self-built homes, minor municipal maintenance projects, or small commercial building construction, deploying large-scale sand production lines would not only waste equipment resources but also increase production costs. A daily output of 100 tons strikes the perfect balance.

In certain regions with poor transportation or limited local demand, a 100-ton-per-day sand production line can source materials locally, processing cement clinker and crushed stone into compliant manufactured sand. This approach reduces transportation and time costs while rapidly supplying aggregate materials to surrounding markets.

(二) Core Equipment Configuration

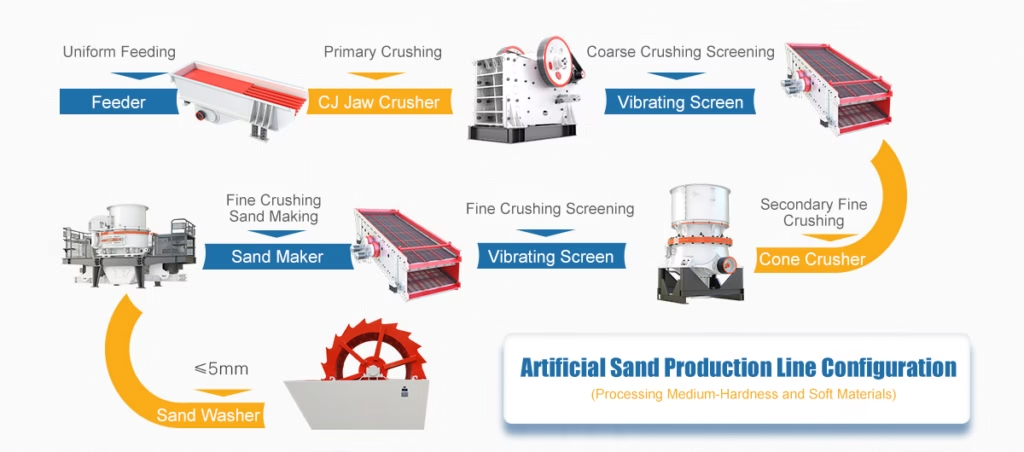

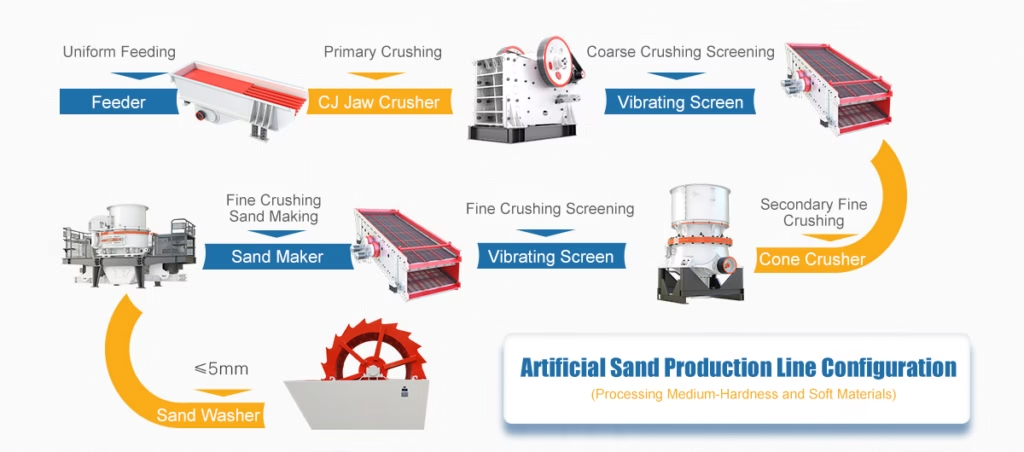

Given the high hardness and abrasiveness of cement clinker, a typical 100-ton-per-day production line employs the following process:

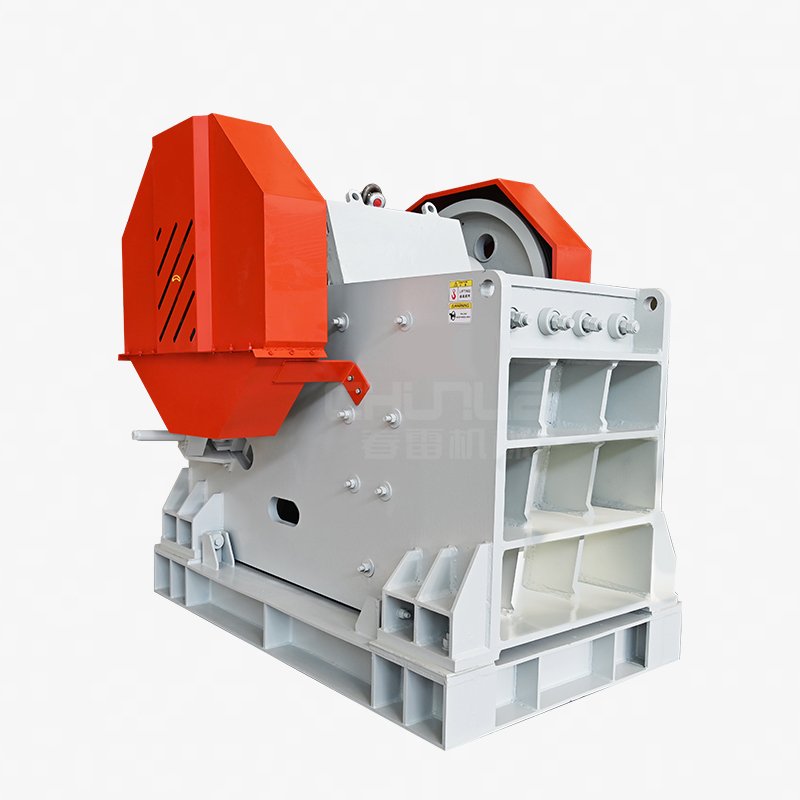

Jaw Crusher

Serves as primary crushing for coarse reduction. Large cement clinker chunks (feed size ≤400mm) are uniformly fed into the jaw crusher via a vibrating feeder for initial breaking. Common models suitable for 100-ton capacity include PE400×600 and PE600×900.

Cone Crusher/Impact Crusher

Used for medium and fine crushing. Material from primary crushing is conveyed via belt conveyor to the cone crusher for further reduction.

Sand Maker

Finely crushed material enters the vertical shaft impact sand maker for shaping and sand production, ensuring excellent finished particle shape.

Ball Mill

If grinding is required, a ball mill can be selected separately. Crushed material is graded via a vibrating screen. Material meeting size requirements is fed into the ball mill for grinding, ultimately producing compliant fine powder.

(三) Investment Return Analysis

For investors, the value of a 100-ton-per-day cement clinker crushed stone sand production line lies not only in the equipment itself but also in its full lifecycle investment returns. Compared to traditional river sand mining, manufactured sand production offers the following economic advantages:

Selecting a 100-ton-per-day cement clinker crushing and sand-making production line involves far more than purchasing a few pieces of equipment. It means choosing a long-term partner who will grow with you, backed by reliable after-sales service and technical support.

With over 30 years of expertise in industrial sand production, CHUNLEI Machinery understands that every client’s production conditions and requirements are unique. Submit your specific raw material parameters and site details, and our technical experts will provide you within 24 hours:

Act now to receive a solution tailored specifically for your needs.

A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill, wet rod mill. Different from the ball mill is built-in rod mill is a steel rod type grinding body, the use of cy...

View detailsThere are two kinds of ball mill gears: large gear and small gear, and the large and small gears of ball mill are its important transmission parts, which are responsible for transmitting the power of the motor to the cylinder, so as to d...

View detailsLime powder is a fine white or grayish-white powder primarily produced through processes such as high-temperature calcination, digestion, and refining of limestone. Widely used in construction, environmental protection, metallurgy, chemical engin...

View detailsFluorite Ore Dressing Production Line Process Introduction Fluorite ore beneficiation methods include gravity separation and flotation, which are also divided into gravity separation equipment and flotation equipment. Gravity separ...

View details