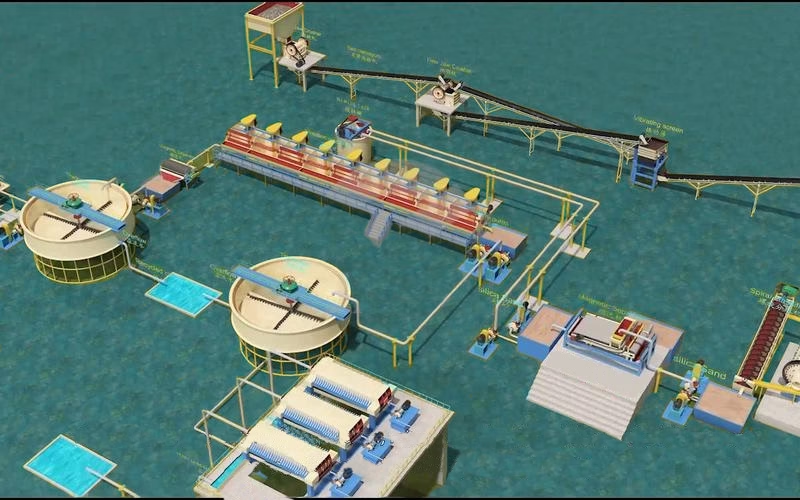

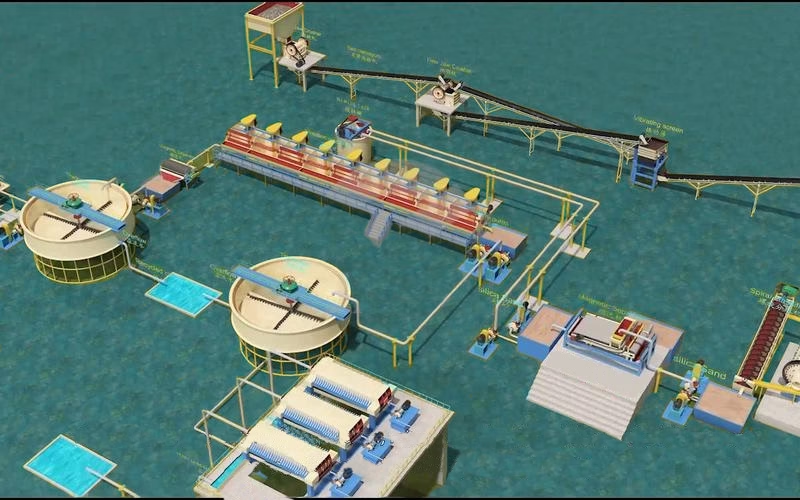

Kaolin Dressing Production Line

Process Introduction

Wet and dry separation are the two main processes of the Spring Thunder kaolin beneficiation process.

The dry separation process is used to process kaolin ores with high whiteness and low gravel content;The wet kaolin beneficiation process is used to process complex kaolin ores,.

What Is Kaolin?

Kaolinite is a non-metallic mineral primarily composed of kaolinite minerals. It features a fine texture, appearing white or light gray, and exhibits excellent plasticity, high whiteness, good chemical stability, and insulation properties.

Alongside mica, quartz, and calcium carbonate, kaolinite ranks among the renowned four major non-metallic minerals. Its exceptional plasticity, whiteness, and chemical stability make it an indispensable core raw material across diverse industries including papermaking, coatings, rubber, ceramics, and pharmaceuticals.

Kaolin processing involves a series of steps to enhance its purity and quality. Through techniques like crushing, grinding, and separation, ordinary kaolin is transformed into a material of significant value across various industries. Consequently, kaolin processing and the equipment used are particularly critical steps that directly determine its commercial value.

What are the processes for extracting kaolin?

Kaolin beneficiation process is a complex and delicate process aimed at removing impurities from the ore through physical and chemical methods to improve the purity and quality of kaolin. The main beneficiation methods for kaolin are:

Re-election method: utilizing the difference in density between kaolin and impurity minerals for sorting. Under the action of gravity and water flow, the impurity minerals with higher density sink, while kaolin rises with the water flow, thus realizing separation. Commonly used re-election equipment are shaking table, spiral chute, etc..

Flotation method: According to the differences in the physical and chemical properties of kaolin and impurity minerals on the surface, the finely ground ore is mixed with water and flotation chemicals, stirred well and then passed into the air, the surface of kaolin is hydrophobic, attached to the air bubbles, and scraped out to become a concentrate; impurity minerals stay in the slurry to become the tailings.

Magnetic separation: For kaolin ores containing magnetic minerals (such as iron minerals), magnetic separation can be used to remove magnetic impurities and improve the purity of kaolin. Commonly used magnetic separation equipment are permanent magnetic separator and electromagnetic magnetic separator.

Chemical beneficiation: For some impurities that are difficult to remove by physical beneficiation, chemical beneficiation can be used. Chemical beneficiation is usually carried out in stirring tanks, reactors and other equipment.

Kaolin Processing Technology: The Meticulous Transformation from Raw Ore to Finished Product

Kaolin processing involves a series of steps to remove impurities and enhance quality. These processes must be tailored based on the raw material’s hardness characteristics and the intended product application. The core techniques can be broadly categorized into two systems: basic milling processes and advanced processing techniques. Particle size control is integral throughout the entire process—from coarse powder (0-3mm) to ultrafine powder (1250 mesh – 3250 mesh). Products with different particle sizes require entirely distinct processing pathways.

The process encompasses four sequential stages: crushing, grinding, classification, and powder collection, enabling large-scale production of products ranging from 20 mesh to 1250 mesh:

- Crushing: Natural kaolin ore typically occurs in large lumps and must be crushed by jaw crushers or cone crushers to a feed size of 15mm–50mm. This prepares the material for subsequent grinding, reducing energy consumption and enhancing efficiency.

- Grinding: The crushed material is mixed with water in a premixer to form a slurry (40–50% solids content). This eliminates dust from dry grinding and ensures uniform grinding.

- Classification Screening: The ground material undergoes classification screening. Finished slurry meeting the target fineness flows through the ball mill’s discharge grid. Undersized coarse particles are automatically returned to the main mill for regrinding, ensuring consistent output. For dry powder applications, the slurry is sent to a filter press for dewatering; for wet material applications, it proceeds directly to downstream processes (e.g., ceramic slip casting, paper coating).

- Flotation: Separates mica and other minerals based on surface properties.

- Magnetic Separation: Removes iron-bearing minerals using magnets.

- Chemical Bleaching: Enhances whiteness using chemical agents.

- Dehydration: Removes excess moisture via thickeners, filters, or centrifuges.

- Drying: Reduces moisture content using equipment like rotary dryers.

- Packaging: Powder meeting fineness requirements is separated and collected by airflow into dust collectors for packaging. This stage requires ensuring dust collection efficiency to prevent environmental pollution from dust leakage.

| Process Step | Main Equipment Used | Purpose |

| Crushing | Jaw Crusher, Cone Crusher | Reducing ore size |

| Grinding | Ball Mill | Grind ore into powder or finer particles |

| Classification | Screens, Hydrocyclones | Separate particles to ensure uniformity |

| Impurity Removal | Sanding Equipment, Flotation Machine, Magnetic Separator, Mixing Tank | Removing impurities |

| Dewatering | Thickeners, Filters, Centrifuges | Removing excess water |

| Drying | Rotary Dryer, Drum Dryer | Reducing moisture content |

Advantageous features of Kaolin Dressing Production Line

- Improve product quality: Through the combination of multiple methods such as re-election, flotation, magnetic separation, chemical beneficiation, etc., the impurities in kaolin ore can be precisely removed, and the grinding and classification process can make kaolin reach the required particle size distribution, so as to make it meet the stringent requirements of different industries such as ceramics, paper, rubber, plastics, etc. for kaolin products.

- Full use of resources: Beneficiation process can make the original difficult to use resources to be effectively developed, can be through the corresponding process of these associated resources for the comprehensive recovery, improve the overall utilization of mineral resources, to achieve the maximum utilization of resources.

- High production flexibility: kaolin beneficiation process is rich and varied, according to the nature of kaolin ore, grade, impurity content, as well as the end use of the product and market demand, flexible selection and combination of the most suitable beneficiation process, to achieve customized production of products, improve the market competitiveness of enterprises .

- Economic benefit enhancement: The unit cost of kaolin beneficiation can be reduced by improving the resource recovery rate, optimizing the process flow, and reasonably selecting equipment and chemicals. After beneficiation and purification of kaolin products can be used in high-end fields, thus enhancing economic benefits.

- Low Consumption and Low Pollution: In the beneficiation process, energy-saving equipment and reasonable process technology are adopted to reduce the energy consumption in the production process and reduce the risk of pollution to the environment.

How To Choose The Right Kaolin Dressing Production Line For Sale

Choosing the right Kaolin Dressing Production Line requires careful consideration of several key factors. This is a guide to help you understand how Kaolin Dressing Production Line works.

Understanding your project needs

Begin by assessing the specific needs of your project. Consider the size of the beneficiation, the climate of the location and the type of material required. Different projects require different production levels, mixing accuracy and environmental standards. Be sure to thoroughly evaluate these factors before making a decision.

Considering equipment output

Plant capacity is critical. Match the capacity of the equipment to your project schedule. For large projects, choose a high-output model to meet demand. For smaller or segmented projects, a mid-sized or small plant may be more appropriate.

Focus on environmental factors

As environmental regulations continue to tighten, it is vital that plants are eco-friendly. Choose equipment with advanced environmental features, such as low-noise design. This not only ensures compliance, but also enhances your company’s image.

Prioritize stability and ease of operation

Stability and ease of operation have a direct impact on efficiency and cost. Choose a plant with automated control systems to minimize human error and increase productivity. Also, consider maintenance costs and the lifespan of key components to ensure consistent performance over time.

Evaluating after-sales service and technical support

Reliable after-sales service and timely technical support are critical. Good support can solve problems quickly, minimize downtime and keep your project on track.

Plan your budget wisely

While the initial investment in mineral processing can be high, choosing durable, stable equipment will provide better returns in the long run. So it’s important to consider not only the purchase price, but also the operating costs, maintenance costs and potential environmental impact.

By taking these factors into consideration, you can find the beneficiation line that best suits your project’s needs, ensuring smooth operation and maximizing your investment.

What Projects Kaolin Dressing Production Line Can Be Used in?

What are the different uses of Kaolin Dressing Production Line? Here are a few ideas that are often used Kaolin Dressing Production Line for sale, highlighting their unique features. When choosing a Kaolin Dressing Production Line, consider factors such as the temperature of the material and climate, not just the application area.

Ceramic Industry

Kaolin has excellent molding, sintering and glazing properties, and is one of the most important raw materials in the ceramic industry. Its plasticity makes ceramic blanks easy to mold, while its sinterability ensures the stability and strength of ceramic products at high temperatures.

Paper Industry

As a filler and coating for paper, kaolin can significantly increase the density, whiteness and smoothness of paper, thus improving printing performance and reducing paper costs. In the paper industry, kaolin is also widely used in the production of various high-grade paper.

Coating Industry

As an important filler and pigment, kaolin can not only improve the covering power, adhesion and weathering resistance of paints, but also reduce the cost of paints. In addition, kaolin can make the paint maintain good dispersion and fluidity after long time storage. Kaolin plays an important role in the fields of interior and exterior wall coatings, high-grade paints and inks.

Rubber Industry

As an important filler and reinforcing agent, kaolin can improve the physical properties and mechanical strength of rubber. In addition, kaolin is able to adsorb harmful substances and impurities in rubber and improve the purity and quality of rubber. Therefore, kaolin plays an important role in the production of tires, conveyor belts, sealing strips and other rubber products.

Petrochemicals

Kaolin can be used as a carrier for catalysts to improve the activity and stability of catalysts; it can also be used as a medium for chemical reactions to promote chemical reactions. In addition, kaolin can be used in the production of polymer materials, such as polyethylene and polypropylene.

The beneficiation production line can be adapted to the needs of different industries, such as metallurgical industry, chemical industry, building materials industry and so on.

Steel-industry

Iron and steel industry is the most important application industry of iron ore beneficiation production line.

Mining-Industry

Mining enterprises can realize the efficient development and utilization of iron ore resources through iron ore beneficiation production lines.

Chemical industry

Iron is used in the production of some chemical products, and the synthesized chemical products are widely used in the fields of paints, plastics, rubber and water treatment.

Construction industry

In the building materials industry, iron ore beneficiation production line can be used to process some tailings or slag containing iron ore, etc..

What is the Price for Kaolin Dressing Production Line?

When considering Kaolin Dressing Production Line, it is important to match your budget with the right model. Whether you need a cost-effective solution or high capacity production, both series of ChunLei Machinery offer excellent options to meet your specific needs.

As one of the old brand mining machinery manufacturers in Henan, Chunlei Machinery strictly controls every product for sale with more reliable quality. Chunlei has its own R&D team and production site, and sells directly, enjoying factory super low price. What are you waiting for? Contact us immediately!

REQUEST A QUOTE

If you need to know more product information

Submit your product intentions and needs, we will contact you in the first time!