Recently, an African client contacted us seeking to concentrate gold and sulfur from sulfur ore. Based on the client’s requirements and existing equipment, and to prevent tailings loss, our engineer recommended the Model 900 spiral chute.

After a period of operation, the client reported that the entire production line runs smoothly with efficiency increased several times over. Most importantly, the addition of the spiral chute boosted gold and sulfur extraction rates by 40% compared to previous methods. The client expressed great satisfaction with our recommended equipment, repeatedly praised the engineer’s professionalism, and indicated a desire for long-term cooperation.

The core reason lies in its role as a highly efficient, low-cost, and environmentally friendly “pre-concentration” method. It enables the early rejection of large volumes of useless waste rock (tailings) before subsequent complex processes like flotation or oxidation, thereby substantially reducing overall mineral processing costs and energy consumption.

What is the core function of a spiral chute?

In mineral processing, the spiral chute serves to “discard tailings” and perform “pre-concentration.”

1. What is “pre-concentration”?

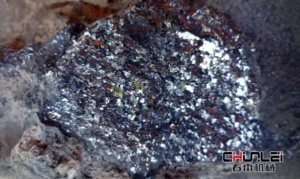

After ore undergoes primary crushing and grinding, it produces large quantities of high-density sulfide particles that are either individually liberated or enriched with gold, alongside substantial amounts of low-density gangue particles.

The spiral chute efficiently separates the feed into three fractions based on density and particle size: concentrate, middlings, and tailings.

2. What is “discarding tailings”?

Through pre-concentration in the spiral chute, 50%-70% of the qualified tailings can be discarded at a coarser particle size (avoiding over-grinding), achieving the effect of “recovering early what can be recovered and discarding early what can be discarded.”

For sulfide gold ores, the “pre-concentration and tailings rejection” approach embodied by spiral chutes represents one of the core principles of modern mineral processing, aimed at maximizing economic efficiency. Spiral chutes contain no powered components, relying solely on gravity flow and self-flowing slurry. Their simple structure, compact footprint, ease of operation and maintenance, and near-zero power consumption make them one of the most cost-effective mineral processing devices. They are virtually the preferred equipment for gravity separation processes, especially when handling precious and rare metals such as gold, tin, and tungsten.