Ceramic Ball Mill

- Want to grind hard minerals into fine powder but worried about metal contamination affecting product purity? CHUNLEI ceramic ball mills, featuring fully ceramic linings and grinding media, perfectly solve the contamination issues caused by traditional metal mills, ushering in a new era of ultrafine grinding.

- Capacity:0.65-615t/h,Customizable

- Feeding Size: <25mm; According to Model

- Discharging Size: 0.075-0.4mm; According to Model

What is Ceramic Ball Mill?

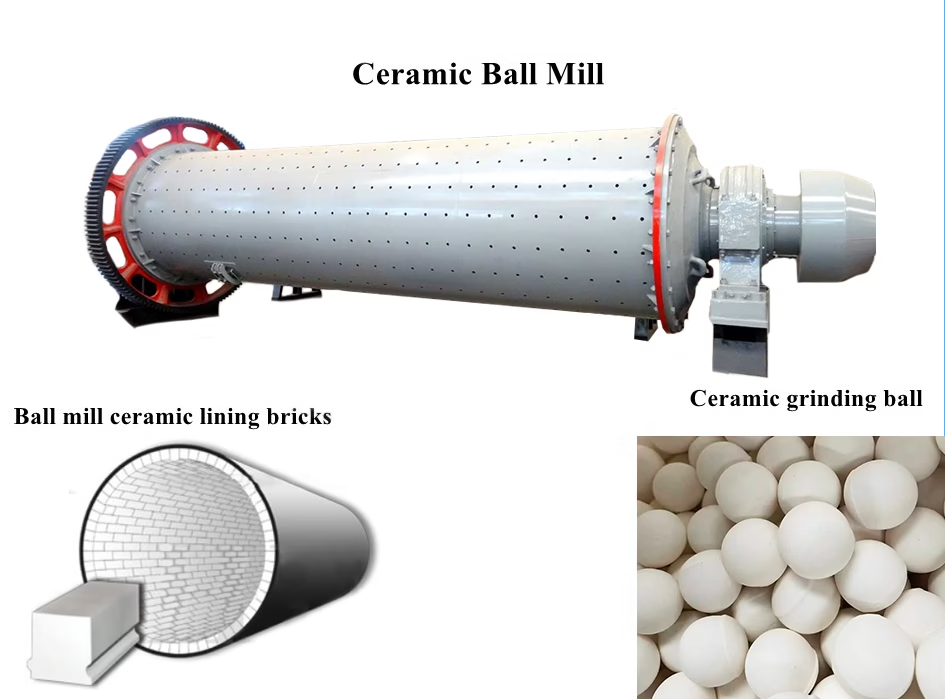

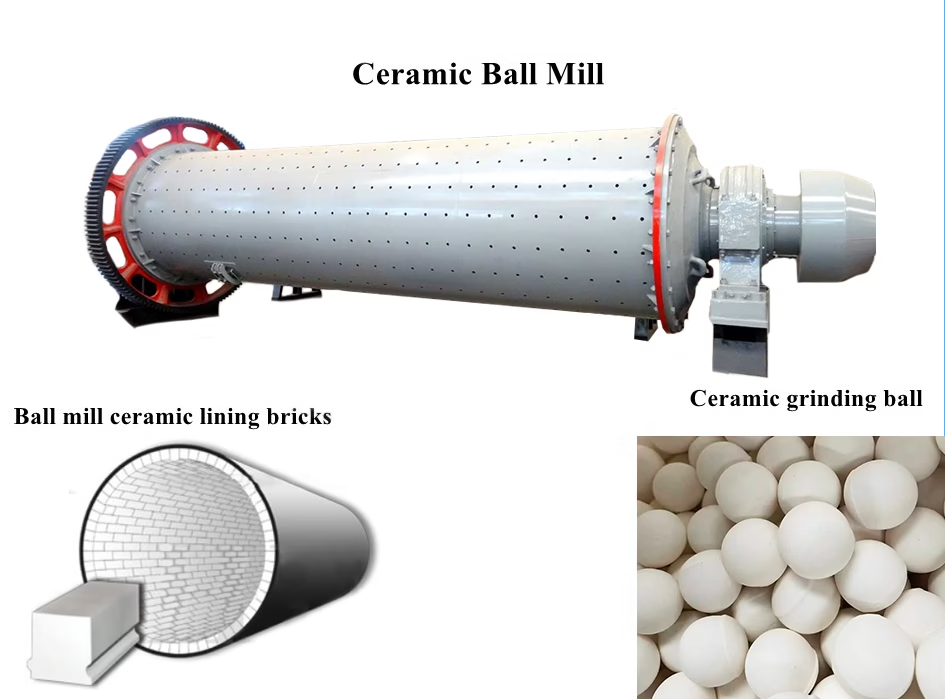

Ceramic ball mills are grinding equipment that replaces traditional metal liners with ceramic liners and uses ceramic balls (such as alumina, zirconia, silicon carbide, etc.) as grinding media. Material is finely processed through impact and grinding by the rotating cylinder driving the ceramic grinding media.

Ceramic Ball Mill Structural Features:

- Compartmentalized Design: The cylinder is divided into coarse grinding and fine grinding compartments, with stepped or corrugated liners optimizing the grinding path.

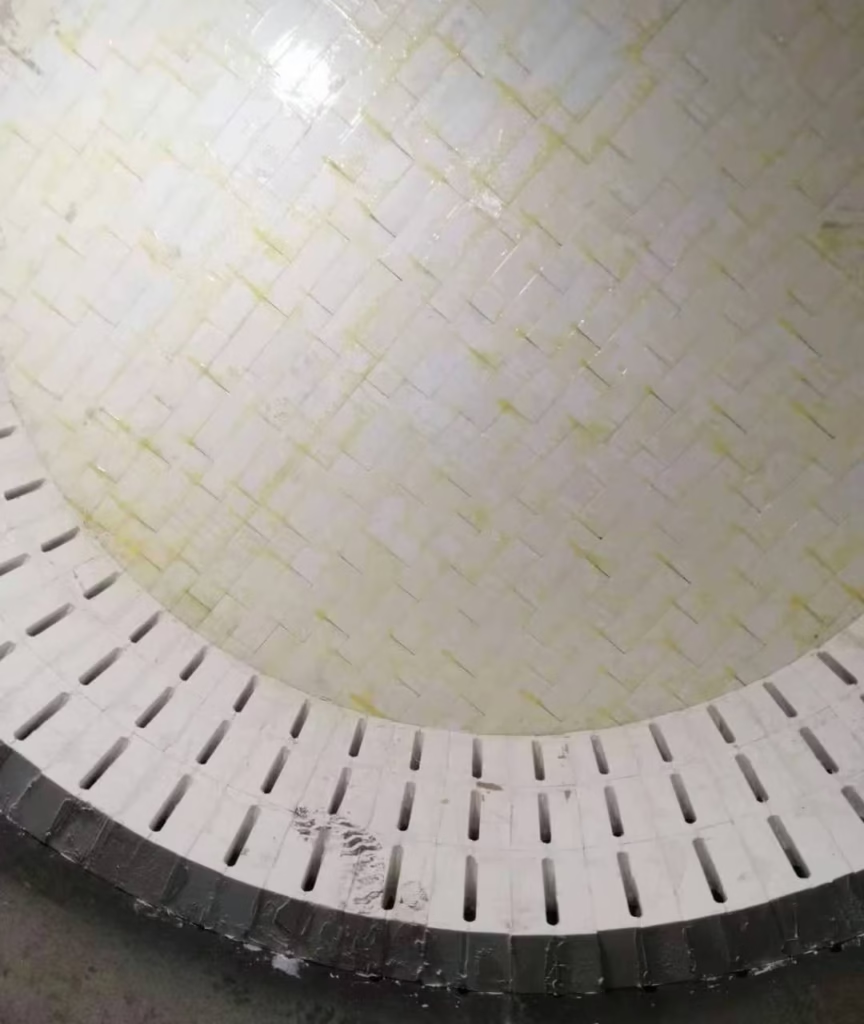

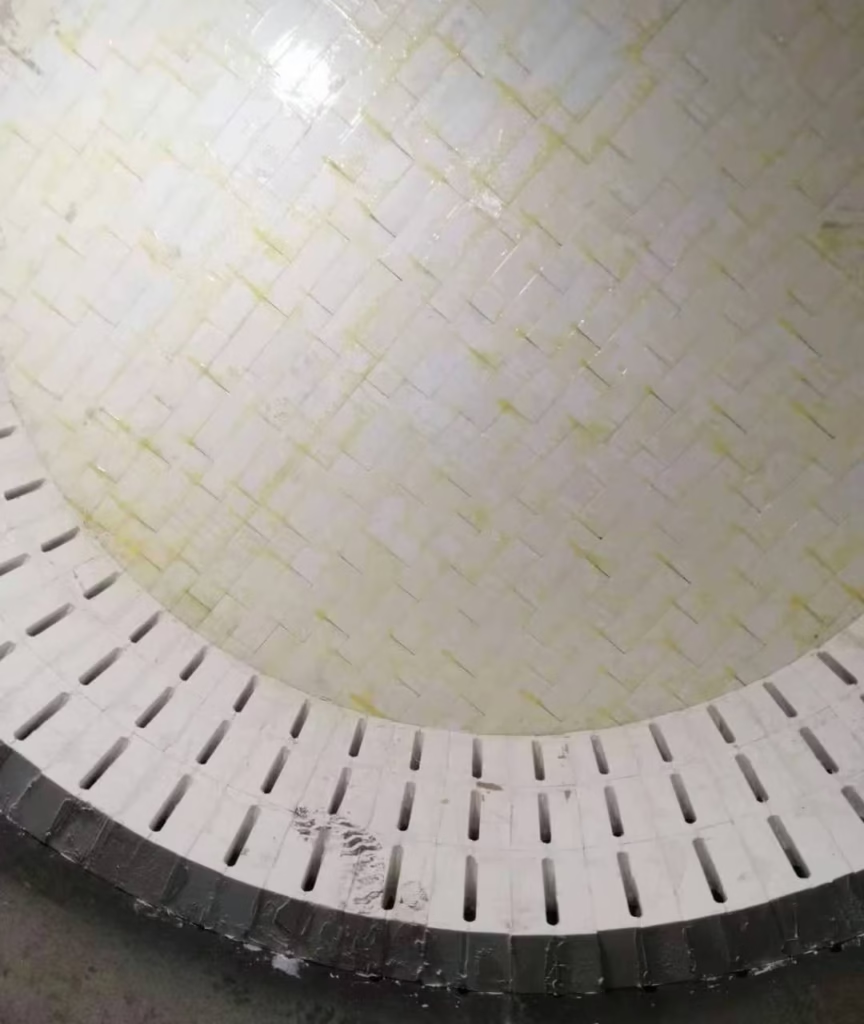

- Wear-Resistant Ceramic Liners: Constructed from materials like alumina and silicon carbide, these liners offer corrosion resistance, wear resistance, and prevent metal contamination.

- Flexible Drive System: Utilizes either peripheral gear transmission or variable-frequency motor drive, supporting seamless switching between dry and wet grinding modes.

Core Functions and Applicable Materials of Ceramic Ball Mills

Core Functions:

- Pure Processing: Utilizing ceramic liners and grinding media, ceramic ball mills eliminate metal ions, meeting stringent purity requirements for materials in industries such as electronic ceramics, pharmaceuticals, and food processing.

- Ultrafine Grinding: By adjusting grinding time, media size, and filling rate, materials can be pulverized to micron-level or even nanoscale fineness.

- Uniform Mixing: Supports blending diverse materials, achieving highly uniform dispersion and compounding.

Applicable Materials:

With its exceptional performance, the ceramic ball mill serves as a “universal grinder” for over 200 materials. It is widely adopted in industries requiring high-purity and precision grinding. Its advantage lies in broad material adaptability, particularly suited for:

- Ceramic Raw Materials: Kaolin, quartz sand, feldspar, clay, etc., ground for tile, sanitaryware, and refractory production.

- Chemical Raw Materials: Iron-free coatings, fuels, and high-end fillers.

- Mineral Resources: Purification and ultrafine grinding of non-metallic minerals like barite, calcite, talc, and bentonite.

- New Energy Materials: Lithium battery cathode/anode materials (e.g., lithium iron phosphate, lithium cobalt oxide, graphite) and solid electrolytes (preventing iron impurities from affecting electrochemical performance).

Wet Grinding vs. Dry Grinding—How to Choose the Most Suitable Process?

| Dry grinding | Wet grinding | |

| Media | Grinding occurs without liquid, with materials and grinding media processed in a dry state. | Liquids (such as water, alcohol, or solvents) are used as dispersants. |

| Equipment Structure | Features a straight cylindrical discharge port equipped with an air extraction system and dust collector. | A funnel-shaped discharge port incorporates an internal spiral mechanism. |

| Working Principle | Material is carried out by airflow, relying on centrifugal force and gravity for grinding. | Water flow propels the material, ensuring thorough mixing between grinding media and material. |

| Advantages | The process is straightforward and direct, eliminating the need for drying. It is suitable for continuous production and handles water-sensitive materials well. | This achieves higher grinding efficiency, finer and more uniform particle sizes, effectively prevents material agglomeration, minimizes dust pollution, and reduces equipment wear. |

| Challenges | Prone to dust generation (requires dust collection system), higher grinding heat, tendency for material agglomeration, and typically lower efficiency than wet grinding | Requires subsequent drying steps, increasing energy consumption and costs; unsuitable for materials that react with water. |

| Applications | Suitable for cement production, dry powder coatings, metal powder processing, and scenarios where materials deteriorate upon water addition | Suitable for industries requiring high fineness and multiple material blending, such as ceramic glazes, chemical slurries, and mineral processing. |

Technical Parameters of Ceramic Ball Mill

| Model | Feeding capacity (t/time) | Shell rotation speed (r/min) | Reference motor (kw) | Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

Note: The output will vary depending on different materials, feed particle size and other factors.

How should one select the size of a ceramic ball mill?

- Production Capacity: Production capacity is the core selection criterion, requiring clarification of the material volume to be processed per hour or per day. For example: If 50-100 tons of ore need to be processed daily, a small ceramic ball mill with a cylinder diameter of 0.9-1.2 meters and length of 0.9-1.2 meters (e.g., model 600×700) can be selected. For daily processing capacities reaching thousands of tons, large-scale equipment with a cylinder diameter of 3-5 meters and length of 5-10 meters is required (e.g., model 3200×4600).

- Feed Size: Larger feed particle sizes require larger-diameter ball mills for coarse grinding using larger grinding media. Smaller feed sizes can be processed in smaller-sized equipment for fine grinding.

- Final Particle Size: How fine does your final powder need to be? In continuous operation, longer ball mills typically produce finer products, while batch ball mills require longer grinding times to achieve the same fineness.

- Material Properties: Material characteristics determine grinding difficulty. Higher Mohs hardness and greater toughness (e.g., silicon carbide) make grinding more challenging, requiring longer residence times or higher power. Selecting a slightly larger capacity or higher-powered model may be necessary to ensure throughput.

What are the differences between ball mills, rod mills, and ceramic ball mills?

Ball mills, rod mills and ceramic ball mills each have distinct focuses in terms of principle, structure, and application. Below is a core comparison table of ball mills, rod mills, and ceramic ball mills, compiled based on equipment structure, working principle, applicable scenarios, and performance characteristics:

| Comparison Dimensions | Ball Mill | Rod Mill | Ceramic Ball Mill |

| Equipment Type | Traditional grinding equipment utilizing steel balls as grinding media | Utilizes steel rods as grinding media, emphasizing line contact grinding | Features ceramic liners + ceramic media (e.g., zirconia balls) to eliminate metal contamination |

| Working Principle | Steel balls are lifted to high altitudes by centrifugal force before being released to fall/tumble, achieving dual impact and grinding effects | Steel rods engage in line contact, selectively grinding coarse particles while allowing fine particles to pass through rod gaps, reducing over-grinding | Ceramic media impacts, compresses, and grinds materials through rotary grinding, supporting both dry and wet grinding modes |

| Grinding Media | Steel balls (diameter 20-125mm), filling rate 40%-50% | Steel rods (diameter 75-150mm, length ≤6.1m), filling rate 35%-45% | Ceramic balls (e.g., high-alumina ceramic balls, zirconia balls) with density 2.6-6.0 g/cm³, low self-abrasion, suitable for high-purity requirements |

| Structural Features | Cylinder length-to-diameter ratio ≈ 1 (primarily short-cylinder type), curved inner surface of end cover liners | Cylinder length-to-diameter ratio 1.5-2.0; end cover liner inner surface forms vertical plane; discharge end hollow shaft features larger diameter | Compartmentalized mill design (coarse grinding chamber + fine grinding chamber) using wear-resistant ceramic liners (e.g., alumina/silicon carbide), supports variable frequency speed control |

| Suitable Materials | Widely applicable to metal ores, cement, chemical raw materials, etc., with exceptional material adaptability | Tungsten-tin ore, rare metal ore gravity/magnetic separation; replaces cone crushers for coarse crushing; produces construction aggregates | High-purity ceramic raw materials (e.g., kaolin, quartz sand), electronic ceramics, pharmaceutical/food-grade materials—eliminates metal contamination |

| Discharge Method | Overflow type/grate type: Grate plates are prone to clogging but discharge material quickly; overflow type is easier to manage but has longer residence time | Overflow/open type; no grate plate; large discharge end diameter supports peripheral discharge (end/mid-section) | Flared discharge port + screw conveyor (wet grinding), straight discharge port + air extraction dust removal (dry grinding), fineness controlled by processing time |

| Particle Size Control | Can achieve 80% passing 200 mesh, but severe over-grinding occurs | Product particle size uniform (80% ≤ 2.0-0.5mm), minimal over-grinding, suitable for coarse grinding or pre-grinding | Flexible fineness adjustment (80 mesh to nanoscale), particularly suited for ultrafine powder processing (e.g., 0.05mm zirconia beads) |

| Energy Consumption and Efficiency | High capacity but significant energy consumption (only 5%-7% of input power used for effective grinding) | Capacity approximately 15%-20% lower than ball mills, but 20%-30% more energy-efficient in specific scenarios (e.g., wet grinding) | 10%-15% energy savings (wet grinding mode); autotransformer reduced-voltage start reduces current draw; ideal for small-batch/high-value material production |

| Advantages and Disadvantages | Advantages: Strong adaptability, high capacity, suitable for both dry and wet grinding; Disadvantages: Severe over-grinding, risk of metal contamination | Advantages: Uniform particle size, minimal over-grinding, suitable for coarse grinding; Disadvantages: Low production efficiency, tendency for grinding media entanglement (due to long rod limitations) | Advantages: No metal contamination, energy-efficient and eco-friendly, controllable fineness |

Daily Precautions for Ceramic Ball Mills

- Maintenance of Ceramic Lining and Media: Regularly inspect the ceramic lining for cracks or spalling, which can cause contamination and malfunctions. Simultaneously, ceramic balls will wear down and require periodic screening and replenishment to maintain grinding efficiency and purity.

- Strictly Prevent Metal Contamination: This is an absolute operational red line. The presence of metallic foreign objects such as iron tools is strictly prohibited, as they will contaminate the entire batch of material and scratch the lining.

- Standardized Operation: Feed material uniformly to prevent overload or dry-running. Inspect brakes before startup.

- Routine Inspections: Check for loose fasteners, monitor for abnormal operational sounds, track bearing temperatures, and assess seal integrity.

- Ensure Lubrication: Use approved lubricants/greases as specified and maintain unobstructed oil passages.

Conclusion

In summary, the ceramic ball mill is far more than a simple crushing tool. It serves as the guardian ensuring high material purity and the precision engineer achieving ultrafine powders. Whether opting for wet grinding to pursue ultimate fineness or employing dry grinding for efficient, direct processing, its core value lies in providing a pure, reliable foundation for the development of high-end materials.

If you’re seeking solutions to enhance product purity or overcome grinding challenges, delve deeper into ceramic ball mills and evaluate their potential. Contact us today.