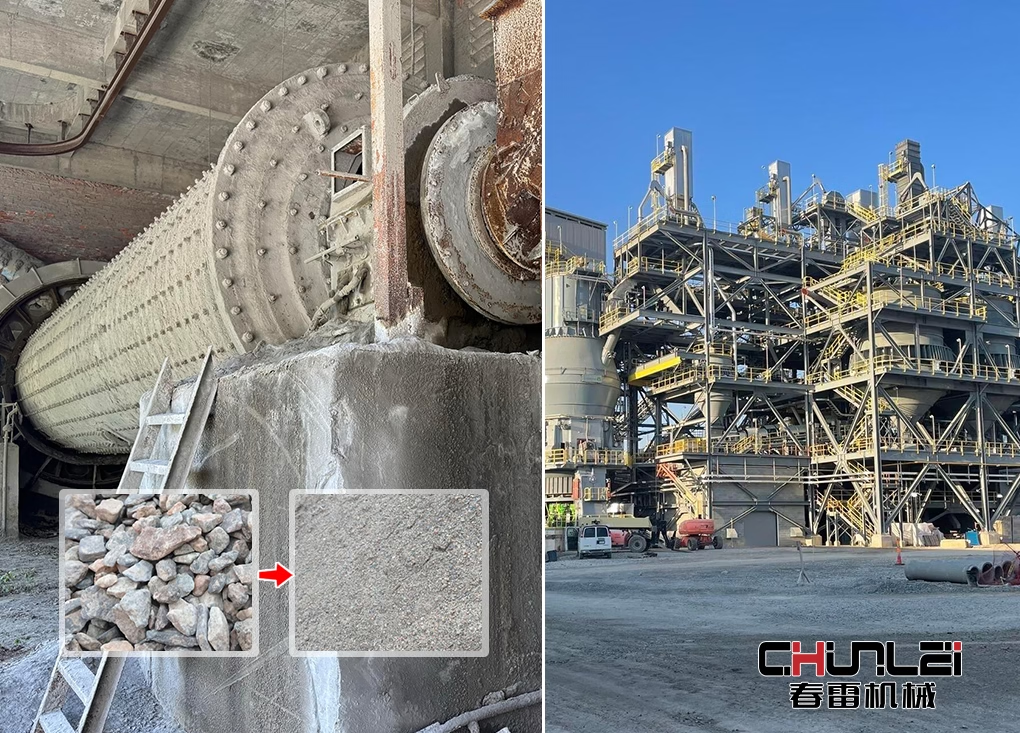

In the production of cement clinker at cement grinding plants, the ball mill is undoubtedly the most central and widely used equipment. It serves as the core link between clinker calcination and the final cement product, grinding the hardened clinker—fired at high temperatures—into fine cement powder.

Positioning and Process Flow of Cement Clinker Grinding Plants

Cement production is typically divided into three stages: raw material preparation, clinker calcination, and cement manufacturing. The cement manufacturing stage is carried out by cement clinker grinding plants, primarily involving the grinding of cement clinker. Two grinding methods are commonly used: dry grinding and wet grinding. Dry grinding is widely adopted due to its low energy consumption, simplified process, and ease of automation control.

Ball Mill: The Core Equipment for Cement Grinding

The cement clinker ball mill utilizes simple physical impact and grinding to pulverize and refine cement clinker to a specified fineness, thereby meeting the requirements for cement usage.

Structure of Cement Ball Mills:

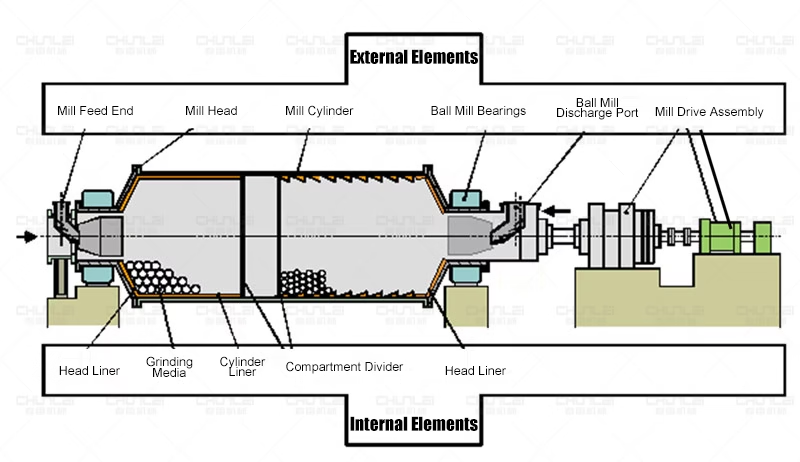

Typically horizontal rotating cylindrical equipment, cement ball mills consist of four main components:

- Feed and Discharge Devices: Located at both ends of the cylinder, responsible for feeding and discharging materials respectively.

- Grinding Core Assembly: Comprising the cylinder, liner plates, grinding media, and compartment plates, this is the critical structure performing the grinding function.

- Drive and Support System: The main bearing serves as the core of the drive mechanism. The transmission system transfers power from the motor to the cylinder, typically comprising an electric motor, reducer, and gearing.

- Auxiliary Systems: Comprising lubrication, cooling, and electrical/control systems, these support the main unit’s safe, stable, and efficient operation.

Working Principle of Cement Ball Mills:

The operating principle relies on the synergistic effects of centrifugal force and gravity. The horizontally positioned cylinder rotates slowly under motor drive. As the cylinder turns, steel balls are lifted to a certain height before cascading down like a waterfall, delivering intense impact and grinding to the material. Simultaneously, interactions between the steel balls themselves and between the balls and the cylinder liner plates further refine the grinding process. Typical ball mills feature a two-compartment or multi-compartment grid design:

- First Compartment (Coarse Grinding): Large-diameter steel balls and stepped liners break down coarse material.

- Second Compartment (Fine Grinding): Smaller steel balls and flat liners further refine the crushed material, enhancing grinding precision.

Material passes through the compartment partition into the second compartment and is ultimately discharged through the discharge grate, completing the grinding process.

Types and Technical Advantages of Cement Ball Mills

Based on process requirements, cement ball mills can be categorized into two types:

Standard Cement Ball Mill: Primarily used in closed-circuit systems, it offers high grinding efficiency, large output capacity, uniform product particle size, and low power consumption. When grinding slag cement, output can increase by 15%-20%, power consumption decreases by approximately 10%, and the finished product temperature is lower, facilitating storage.

High-Fineness, High-Output Cement Ball Mills: Suitable for open-circuit systems, these incorporate specialized internal classification, activated liners, or screening devices. They significantly enhance grinding efficiency, effectively separate qualified fine particles, and prevent over-grinding.

Additionally, ball mills feature the following prominent characteristics:

● Strong Adaptability: Process materials of varying hardness and particle size;

● Continuous Operation: Support 24-hour uninterrupted running;

● Flexible Adjustment: Product fineness controllable by modifying steel ball gradation, filling rate, and rotational speed;

● Dual-Processing Capability: Suitable for both dry and wet production methods, even integrating drying and grinding functions.

Key Performance Influencing Factors

- Grinding Media Gradation: Steel ball size, type, and proportion must be optimized based on material hardness, particle size, and target product fineness.

- Fill Rate: The percentage of total volume occupied by steel balls, material, and other fillers relative to the effective cylinder volume. Typically ranging between 25%-35%, it directly impacts power consumption and output.

- Internal Ventilation: Effective ventilation promptly removes fine particles and moisture from the mill, preventing over-grinding, ball clogging, and liner fouling. This enhances grinding efficiency and reduces power consumption.

Operation and Maintenance

To ensure long-term stable operation of the ball mill, a scientific maintenance system must be established:

● Lubrication Management: Regularly apply clean lubricating oil to critical components such as bearings and gears, ensuring oil temperature does not exceed 80°C;

● Wear Part Inspection: Inspect and replace wear-prone components like grinding rollers, liners, and steel balls approximately every 500 operating hours;

● Foundation Installation: Equipment must be mounted on a level concrete foundation secured with anchor bolts, allowing a minimum 15-day curing period for the cement;

● Commissioning and Testing: Conduct no-load trial runs for at least 1 hour and load testing for no less than 8 hours to verify absence of abnormal noise, vibration, or air leakage;

● Operating Procedures: Operators must undergo specialized training to understand equipment principles and emergency response protocols.

Conclusion

The cement ball mill is essentially a large rotating cylinder. It serves not only as the key equipment for material refinement but also as the cornerstone for ensuring cement quality and production efficiency. Every component design is critical. CHUNLEI Machinery ball mills not only deliver industry-leading performance but also offer unmatched price advantages. As a manufacturer and direct seller with decades of mining industry expertise, we strive to deliver quality and pricing that resonate with our customers.

If you are considering investing in grinding equipment or have any inquiries, please contact us anytime. We will spare no effort in addressing all your concerns with our professional expertise. Reach out to us now!