Impact Crusher

518A variety of models are available | Get the free price list! Impact crushers are categorized into PF impact crushers and CI impact crushers. PF Impact crusher, also called small diameter impact crusher. CI Impact C...

View detailsSearch the whole station Hot Product Catalog

As a vital non-metallic mineral resource, dolomite faces growing demand for high-purity, fine-grained powder. A dolomite grinding plant specializes in processing dolomite into fine powder for diverse industrial applications. How does such a facility transform raw ore into high-value-added products? This article provides a comprehensive analysis of the production process, equipment configuration, and entire manufacturing journey within a dolomite grinding plant.

Dolomite is a natural mineral with the chemical composition CaMg(CO₃)₂. It serves as a vital source of magnesium and exhibits excellent properties as a refractory material, eco-friendly neutralizing agent, and functional filler. With a hardness of 3.5-4, specific gravity of 2.85-2.9, and predominantly grayish-white color resembling limestone, it finds extensive applications in metallurgy, construction materials, chemical engineering, environmental protection, and other fields.

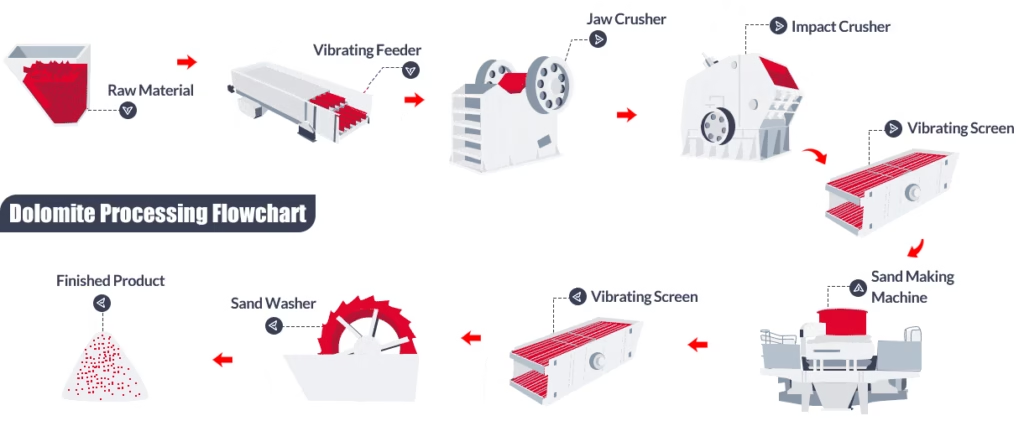

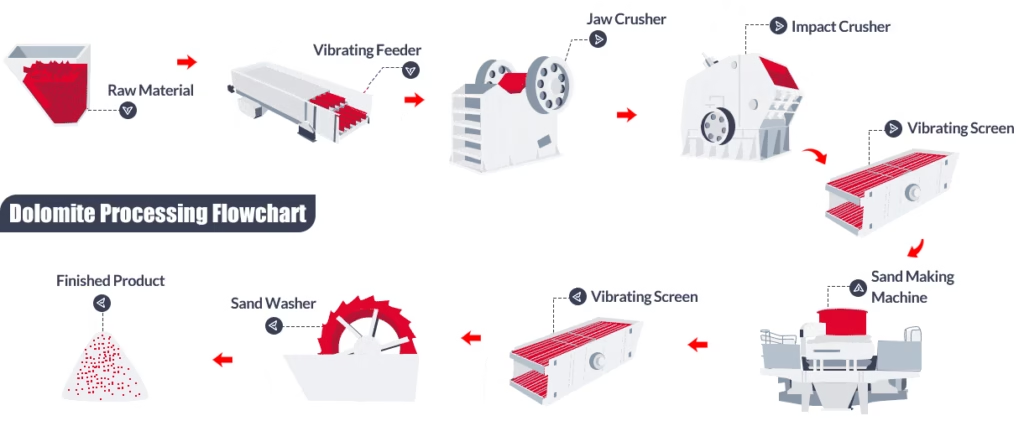

The core processing flow for dolomite can be divided into four major stages: crushing, grinding and classification, collection and dust removal, and deep processing. The product fineness, purity, reactivity, and investment scale determine different process routes.

Pre-treatment is essential to obtain “clean material” with stable composition and appropriate particle size.

Crushing: Large dolomite blocks are first broken into smaller pieces (approximately 100-200mm) using a jaw crusher. These are then further crushed to sizes below 30-50mm via a cone crusher or impact crusher, preparing the material for subsequent processing.

Impurity Removal: For products requiring high purity, crushed material undergoes washing or magnetic separation to remove contaminants like soil, grass, and iron-bearing impurities.

This is the most critical step, directly determining the final product’s fineness, particle shape, and production capacity.

Grinding:

Grinding determines the product’s fineness. The choice of equipment directly impacts the final product’s performance, output, and economic efficiency. Below is a detailed comparison of mainstream grinding equipment:

| Characteristics | Raymond Mill | Vertical Mill (VM) | Ball Mill |

| Applicable Product Fineness | 80-400 mesh (0.175-0.045mm) | 80-600 mesh (down to 0.02mm) | 100-600 mesh (finer possible but low efficiency) |

| Working Principle | Centrifugal oscillating grinding rollers | Hydraulic roller pressure grinding | Ball impact and grinding |

| Single-Unit Capacity | Small to medium capacity (1-30 tons/hour) | Large capacity (5-100+ tons/hour) | Medium to large size, but low efficiency |

| Power Consumption | Higher | Lowest (20-30% energy savings vs. Raymond mill) | Highest |

| System Complexity | Moderate | Moderate, high integration | High (requires large classifier) |

| Dry/Wet Process | Dry Process | Dry process (can integrate drying) | Dry or wet processing possible |

| Automation Level | General | High, easy centralized control | Average |

| Footprint | Low | Compact (Vertical layout) | Significant |

| Product Features | Wide particle size distribution with some coarse particles | Concentrated particle size distribution, favorable particle morphology | Narrow particle size distribution, but prone to over-grinding |

| Investment Cost | Low (Entry-level preferred) | Higher (for large-scale projects) | High (significant system investment) |

| Maintenance Cost | Moderate, easy replacement of wear parts | Lower, stable operation | High (high steel consumption and energy consumption) |

| Core Advantages | Mature technology, low investment, simple maintenance | Low energy consumption, high output, excellent environmental integration | Capable of wet processing with high product purity |

| Major Drawbacks | Low upper limit of fineness, relatively high energy consumption | Not suitable for producing ultra-fine powders (>800 mesh) | Extremely high energy consumption, high noise levels, significant pollution |

| Optimal Application Scenarios | Mid-to-low-end markets with less stringent fineness requirements (e.g., building materials, fillers) | The mainstream choice for modern large-scale powder processing plants, used for bulk powders in building materials, metallurgy, environmental protection, etc. | Used for specialized requirements (e.g., wet ultra-pure grinding) |

Classification:

Classification controls the particle size distribution of the product. After grinding, the material enters the classifier where centrifugal force generated by a high-speed rotating turbine separates qualified fine powder carried away by airflow, while coarse particles are flung toward the cylinder wall and fall back onto the grinding disc for re-grinding. Adjusting the turbine speed controls the maximum particle size and particle size distribution of the final product.

Qualified fine powder enters the cyclone separator for collection. Exhaust gas containing trace fine particles enters the dust collector for filtration, ensuring compliance with environmental standards.

As a traditional base material, dolomite boasts a vast and stable market. Its role as a key ingredient in photovoltaic glass and new energy applications also drives sustained growth in emerging sectors.

As a mining machinery specialist, CHUNLEI remains committed to providing clients with comprehensive solutions—from ore analysis and process design to equipment supply, installation commissioning, and operational training.

A variety of models are available | Get the free price list! Impact crushers are categorized into PF impact crushers and CI impact crushers. PF Impact crusher, also called small diameter impact crusher. CI Impact C...

View detailsThis article provides a comprehensive guide to granite production lines: a complete design from crushing and screening to grinding. Granite, renowned for its hard texture and attractive color, is widely used in construction and serves as an exc...

View detailsIn gold ore processing, every incremental improvement in recovery rate directly impacts a company's input-output profitability ratio. Selecting the appropriate equipment for grinding gold ore is the primary factor determining gold recovery effici...

View detailsGold Mine CIP - Carbon in pulp Process CIP Introduction Gold CIP (Carbon in Pulp) is a non-filtered cyanide carbon slurry process that recovers gold from cyanide slurry through activated carbon adsorption. Gold CIP is the ideal c...

View details