Steel Slag Processing Production Line

Though steel slag appears to be low-cost waste material, crushed and purified slag boasts high iron content, soaring prices, and significant market demand. Processed steel slag can be utilized as a smelting flux aid, cement raw material, construction aggregate, road aggregate, brick material, slag fertilizer, and more. Improper disposal of these residues can easily cause environmental pollution. So how can iron resources be maximally recovered from steel slag? CHUNLEI possesses extensive experience in iron resource recovery and provides complete steel slag processing production line equipment.

What is steel slag?

Steel slag is the waste residue discharged during steelmaking, a high-volume industrial solid waste accounting for approximately 15%-20% of crude steel production. Depending on the type of steelmaking furnace, it can be classified as converter slag, blast furnace slag, or electric furnace slag. Steel slag primarily consists of calcium, iron, silicon, magnesium, and trace amounts of oxides such as aluminum, manganese, and phosphorus. Among these, calcium, silicon, manganese, and other trace elements can also serve as effective fertilizers for acidic soils.

Steel Slag Production Line Process

The processing of steel slag primarily involves crushing, grinding, screening, and magnetic separation. Magnetic separation serves as the core method and the most critical step.

Small-scale steel slag production line: Material is conveyed to a crusher for primary crushing. The crushed material is then transported via a conveyor to a magnetic drum below. Iron-containing magnetic particles are flung forward from the drum, while non-magnetic materials fall directly to the rear and are conveyed to the side, achieving efficient purification.

Large-scale steel slag production line: Steel slag is first crushed into small pieces by a jaw crusher. These are then screened by a vibrating screen. Qualified material proceeds to a cone crusher for secondary crushing, while unqualified material is returned to the jaw crusher for reprocessing. The small particles from secondary crushing are sent to a ball mill for grinding. After grinding, the material is conveyed to a drum magnetic separator for magnetic separation and purification. Some projects require dehumidification and dry separation after ball mill grinding, employing wet magnetic separators. The material is then sent to magnetic separators for final purification.

Core Equipment for Steel Slag Processing

Magnetic separation is widely recognized as the core process in steel slag treatment, and the selection of magnetic separation equipment directly impacts iron recovery rates. Common magnetic separation devices include magnetic drums, belt magnetic separators, and magnetic separators. Each possesses unique design principles, application scenarios, and performance characteristics. Proper selection and configuration of these devices can significantly enhance production efficiency, product purity, and protect downstream equipment from damage.

Magnetic Drum

Typically mounted as the main drum atop a belt conveyor, the magnetic drum captures ferrous materials as they pass through. These materials adhere to the drum surface and are automatically shed when the drum rotates into a non-magnetic zone, while non-magnetic materials freely fall away.

Belt Magnetic Separator

Also known as a self-discharging magnetic separator, this unit is suspended above a belt conveyor. As material moves across the conveyor belt, ferromagnetic impurities are attracted beneath the separator and ejected to the side of the conveyor by a continuously operating discharge belt. Non-magnetic material continues to be transported with the belt.

Magnetic Separator

Designed specifically for material separation, magnetic separators utilize high-performance permanent magnets to generate a powerful and stable magnetic field. They efficiently and precisely separate iron-containing magnetic materials from steel slag, enabling refined sorting and recovery of different magnetic materials. Magnetic particles are extracted and isolated externally, while non-magnetic materials fall directly behind the magnetic separator.

Processing steel slag typically requires the combined use of magnetic drums and magnetic separators to maximize iron resource recovery.

| Equipment Type | Design Features | Key Features | Typical Application Locations | Magnetic Field Strength | Applicable Materials |

| Magnetic Drum | Permanent magnet/electromagnetic drum integrated with conveyor belt | Continuous automatic iron removal without shutdown | Conveyor belt transfer points, head pulleys | Medium-High (3000-8000 Gauss) | Dry/wet bulk materials, particle size <300mm |

| Belt Magnetic Separator | Independent suspension magnetic system + iron-discharging belt | Non-contact iron removal protects equipment | Above the conveyor belt | High (8000-15000 Gauss) | Dry bulk materials, deep material layers, large iron pieces |

| Magnetic Separator | Professional sorting structure with multiple models available | Precision sorting recovers valuable minerals | Specialized sorting processes | Adjustable, Wide Range | Minerals slurry, dry powder, fine-grained materials |

Benefits of Steel Slag Recycling

Steel slag recycling is a green industry offering economic, environmental, and social benefits, with advantages that are readily apparent.

- Recovering High-Value Metals: Efficiently extracts 8%-15% metallic iron from steel slag, which can be directly reintroduced into steelmaking processes to reduce raw material costs.

- Production of Green Building Materials: Residual tailings can be processed into high-value products such as steel slag micropowder (as a cement substitute) and steel slag aggregate (for road construction and brick manufacturing).

- Reduced Disposal Costs: Eliminates expenses associated with traditional stockpiling, including land use, management, and environmental penalties.

- Rapid Investment Payback: Modern production lines typically recoup investments within 2-4 years, delivering stable long-term returns.

- Zero Resource Waste: Achieves 100% resource utilization of steel slag, reducing natural ore mining and resource depletion.

- Emissions Reduction & Carbon Mitigation: Replacing cement with steel slag microsilica cuts CO₂ emissions by 30%-50%, supporting China’s dual carbon goals.

- Eliminate environmental risks: Eliminate soil and groundwater contamination, dust pollution, and other issues caused by long-term stockpiling.

- Conserve land: Free up vast areas previously occupied by slag piles for sustainable corporate development.

Customer Case

CHUNLEI provides energy-efficient, environmentally friendly, reliable, and low-operating-cost integrated equipment and solutions for comprehensive steel slag recycling.

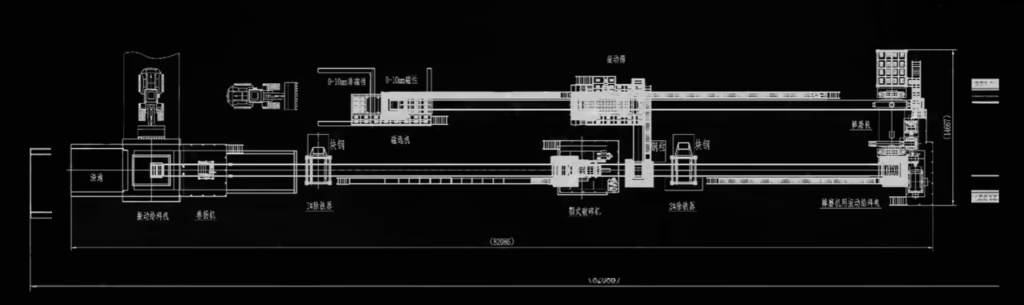

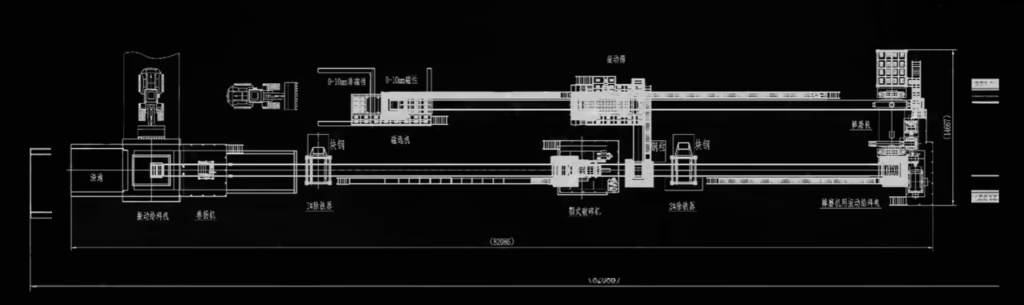

150,000-ton-per-year Eco-Friendly EPC Steel Slag Processing Line

Process Flow:

Feeding — Magnetic separator removes iron pieces and metals from steel slag — PEV hydraulic jaw crusher performs primary crushing — Magnetic separator conducts secondary iron removal to eliminate iron pieces and metals from the jaw crusher output – GMBZ high-efficiency energy-saving rod mill for secondary grinding of steel slag — Eccentric circular vibrating screen for material screening — Magnetic separator for magnetic separation of finished product — Central control room monitors entire production line to ensure stable and efficient operation

150,000 m³/h Processing Capacity

150,000 m³/h processing capacity, wet-wet electrostatic precipitator system, applied in the steel smelting industry. Addresses high-temperature, high-humidity, and high-viscosity dust control during steel slag processing, empowering traditional steel smelting—once a major polluter—to achieve efficient, green, and compliant dust emissions.

What is the Price for Steel Slag Purification Production Line?

When considering Steel Slag Purification Production Line, it is important to match your budget with the right model. Whether you need a cost-effective solution or high capacity production, both series of ChunLei Machinery offer excellent options to meet your specific needs.

As one of the old brand mining machinery manufacturers in Henan, Chunlei Machinery strictly controls every product for sale with more reliable quality. Chunlei has its own R&D team and production site, and sells directly, enjoying factory super low price. What are you waiting for? Contact us immediately!

REQUEST A QUOTE

If you need to know more product information

Submit your product intentions and needs, we will contact you in the first time!