Search the whole station Hot Product Catalog

The Ultimate Solution for High-Efficient Processing

We offer machines in a full range of sizes and fully customize them to solve any challenge.

High quality . High efficiency . Value creation

We provide a complete range of ball mill models for your selection | Get the free price list!

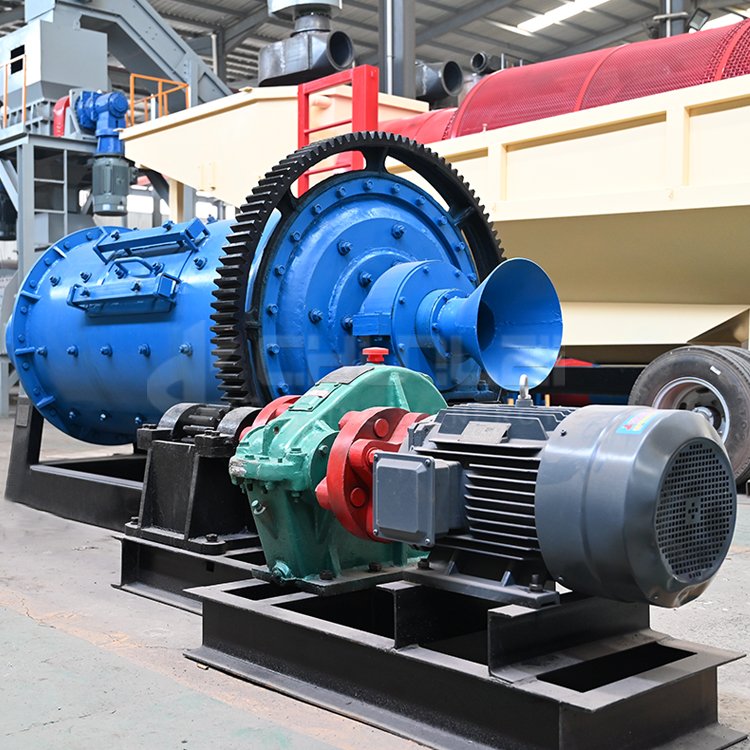

Ball Mill is an important piece of equipment for further grinding of already crushed materials. We load this type of mill with a specific quantity of steel balls as grinding media inside its cylindrical body. It performs dry or wet grinding on various ores and other grindable materials. Our ball mills handle all kinds of ores and materials, and we widely use them in mineral processing, building materials, and the chemical industry.

If you are a beginner and do not know about Ball Mill, tell us your raw material characteristics, finished product requirements, site conditions, production budget, hourly production, and other requirements, we have professional engineers to equip you with a suitable model at a reasonable price.

In this article, we will introduce:

We categorize ball mills into Dry Grinding and Wet Grinding based on your material. We also design them as either Lattice Type or Overflow Type, depending on your ore discharge requirements.; according to the structure, production mode, production materials, fineness, etc., the ball mill type has cement type, mine type, limestone type, ultra-fine type, rod mill type, slag type, high-energy type, vertical, dry, overflow type, lattice type, rotary type, and so on.

Our dry ball mill is purpose-built for cement production lines, delivering reliable, high-efficiency grinding for raw meal, clinker, and finished cement. We engineer it to handle dry materials with precision, using optimized steel ball media and a closed-circuit system to control particle size distribution and ensure consistent cement quality. With a capacity range of 5–150 t/h, it reduces energy consumption by up to 20% compared to conventional mills, while its robust construction minimizes downtime for maintenance—critical for meeting the demanding production schedules of cement plants. Whether you’re upgrading an existing line or building a new facility, we customize the dry ball mill to match your raw material characteristics, production capacity, and site layout, helping you achieve higher output and lower operational costs.

Our wet ball mill is the ideal solution for metal ore processing, designed to grind gold, copper, iron, and other metallic ores efficiently in slurry form. We equip it with a water injection system and overflow/lattice discharge to handle high-moisture ores, ensuring uniform grinding and optimal liberation of valuable minerals. With a capacity of 10–200 t/h, it features a wear-resistant lining and precision bearings to withstand heavy loads, reducing maintenance frequency and extending service life. We tailor each wet ball mill to your ore type, grind fineness requirements, and processing flow, integrating it seamlessly with crushing, flotation, and leaching systems to maximize recovery rates and overall plant performance.

You must consider material properties:

When balancing production capacity, environmental rules, and operational costs, we recommend wet grinding for metal ores and dry grinding for cement production.

For practical applications, contact us—our professional engineers will determine the optimal solution through mineral processing tests tailored to your needs.

| Key Parameters | Ball Mill for Gold Ore Processing | Ball Mill for Cement Plant | Ball Mill for Limestone Grinding |

|---|---|---|---|

| Primary Application | Grinding gold-bearing ore, refractory ore | Grinding raw meal, clinker, finished cement | Grinding limestone for cement, filler, construction |

| Grinding Method | Wet (standard), Dry (optional) | Dry (standard, closed-circuit) | Dry / Wet (dual-purpose available) |

| Capacity Range | 1 – 100 TPH | 5 – 200 TPH | 2 – 150 TPH |

| Feed Size | ≤ 25 mm | ≤ 25 mm | ≤ 30 mm |

| Product Fineness | 200 – 400 mesh (for mineral liberation) | 300 – 450 mesh (uniform particle size) | 80 – 400 mesh (adjustable) |

| Core Feature | High wear resistance, optimized for mineral recovery | Energy-saving, stable output for mass production | High-efficiency, low contamination |

| Customization | Liner type for hard ore, overflow discharge | Large capacity design, closed-circuit system | Special grinding media for soft stone |

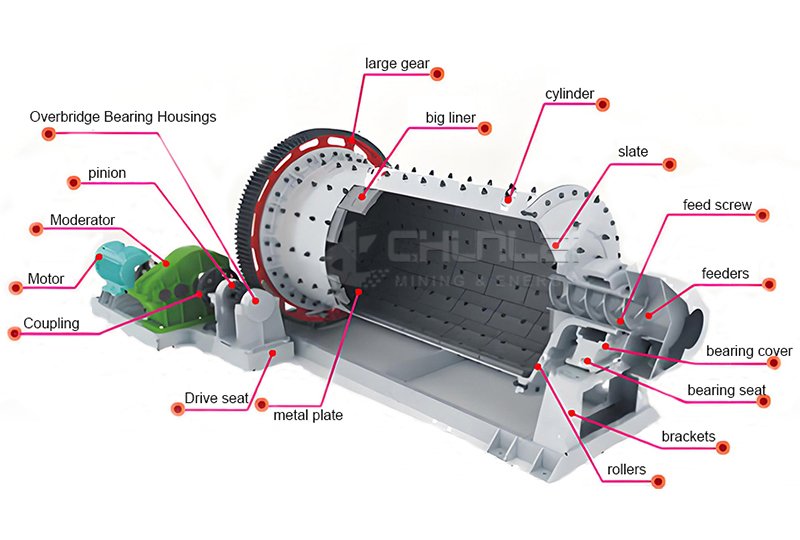

Working Principle of Ball Mill: Ball mill is a kind of external gear, double-compartment horizontal drum mill. The material enters the first hopper from the feeding equipment through the hollow shaft spiral. The hopper has trapezoidal sheath or corrugated sheath, which is equipped with steel balls of different specifications, which fall under the centrifugal force of the cylinder to grind the materials. After rough grinding in the first hopper, the material enters into the second hopper through a single partition plate, the second hopper has a flat graduated plate with steel balls for grinding the material. The ground material is discharged through the discharge plate to complete the grinding process.

Our ball mills come equipped with all the critical components you need: large gears, pinions, hollow shafts, gear rings, large gear rings, steel balls, spacers, machine drives, bearings, end liners, and more.

Let’s talk about the most important component of the ball mill: ball mill steel balls.

We mainly divide ball mill steel balls into two categories: forged steel balls and cast steel balls.

Our ball mill steel balls impact and crush materials effectively, while also providing strong grinding performance.

The crushing performance directly improves grinding efficiency and ultimately boosts your ball mill output.

◎ We equip our ball mills with wave-shaped liners to enhance toughness and maximize contact area between grinding media and ore.

◎ We enhance the grinding effect and deliver more controllable particle size.

◎ We ensure the entire production process runs efficiently and stably.

◎ Factory Direct Pricing & 30 Years of Experience: Own R&D and production facilities, no middlemen, 30 years of mining equipment manufacturing expertise serving global clients;

◎ One-Stop Customization Service: Tailor equipment specifications/functions based on raw material characteristics, production capacity requirements, and site conditions with dedicated engineer-to-engineer design;

◎ Energy Saving & Stable Performance: Utilizes large-diameter self-aligning bearings for low friction and reduced energy consumption. Wear-resistant cylinder liners ensure 99% operational stability while cutting maintenance costs by 30%;

◎ Global After-Sales Service: 1-year free warranty, worldwide spare parts supply, 24/7 technical support, video/on-site installation and commissioning;

◎ Proven Global Success Cases: Equipment exported to 50+ countries including Australia, Spain, and Brazil, serving 1000+ clients across mining, cement, metallurgy, and other industries.

Q: What factors affect the grinding efficiency of a ball mill?

A: Grinding efficiency is affected by the hardness of the material, the feed size, the size and ratio of the grinding media (steel balls), the rotational speed of the equipment, the filling rate and the running time.

Q: How to choose a suitable ball mill model?

A: Ball mills can be selected according to material characteristics, capacity requirements, finished product size requirements and installation site conditions. It is recommended to consult professional technicians to choose customized solutions.

Q: What is the energy consumption of ball mill? Is it energy-saving?

A: The energy consumption of ball mill is related to equipment design, operating parameters and material characteristics. We design modern ball mills with energy-saving features like variable frequency speed control and optimized grinding media ratios, so you can cut energy consumption and achieve green production.

Q: How to choose the grinding media of ball mill?

A: The choice of grinding media (such as steel balls, ceramic balls) depends on the hardness of the material and the requirements of the finished product size. Usually, media with high hardness and good wear resistance are more suitable for grinding hard materials.

Enhance the service consciousness, strengthen the professional skills training, to create a standardized, professional, elite high-quality team, for the user to solve problems.

We mainly produce five series of products: crushers, sand making equipment, mineral processing machinery, gold processing machinery, dryers, rotary kilns, cement production lines, and concrete mixing plants. We also provide customers with project design, process design, and the design and production of standard and non-standard products.

Ceramic ball mills are grinding equipment that replaces traditional metal liners with ceramic liners and uses ceramic balls (such as alumina, zirconia, silicon carbide, etc.) as grinding media. Material is finely processed through impact and grinding by the rotating cylinder driving the ceramic grinding media. …

A variety of models are available | Get the free price list! Wet pan mill, also known as gold ore grinding mill,round mill,Wet discs mill, consists of rollers and discs as the main working parts. It is named after the diameter of the grinding rolls and is mainly used for grinding rock gold ores. It is a multi-pur…

A variety of models are available | Get the free price list! Raymond mill is also called ultrafine grinding equipment, adopts a number of patented technologies such as bevel gear integral drive, internal thin oil lubrication system, arc air ducts, etc., with high grinding efficiency, it is a newer alternative to…

A variety of models are available | Get the free price list! The autogenous mill, also called ultrafine laminar autogenous mill/semi-autogenous mill, is a new type of autogenous mill, which is a kind of grinding equipment with the functions of both medium and fine crushing and coarse grinding. The obvious featur…

In the mining industry, tungsten ore is known as the “teeth of industry” due to its high density and hardness. However, many mine owners face a common challenge during processing: The physical properties of Wolframite and Scheelite are completely different. If you use a “one-size-fits-all” approach, you often end up with l…

Construction and demolition debris—concrete, asphalt, wood, and metals—is the planet’s largest waste stream by volume. For decades, the standard solution was simply hauling it to a landfill. However, with tightening environmental regulations and the soaring cost of virgin raw materials, construction waste utilization has rapidly evo…

Custom-made Jaw Crushers and Cone Crushers have been completed. We are thrilled to announce the successful completion and commissioning of a fully customized crushing solution for our valued overseas client. This project underscores our commitment to delivering precision-engineered, robust machinery tailored to unique operational demands …

Centrifugal concentrators,also known as a mineral processing centrifuge, represent a pivotal advancement in mineral processing, utilizing high G-force fields to achieve superior density-based separation. These machines excel at capturing fine, heavy mineral particles—particularly those smaller than 0.074mm (200 mesh)—that are frequently lost …

We would appreciate it if your message contains the required equipment, the type of project, the export country, and the budget amount so that you can get the most accurate quote!

Contact Us

If you need to know more product information

Submit your product intentions and needs, we will contact you in the first time!