Thermal Balance of Cement Ball Mills definition

The thermal balance of cement ball mills refers to the calculation and analysis of the difference between heat input (such as physical heat carried by materials and mechanical heat generated during grinding) and heat release (such as heat carried out by finished products, heat dissipation from the cylinder, and heat consumed by moisture evaporation) within the mill system. Calculating the thermal balance effectively prevents excessive internal temperatures, avoids cement “false setting” or performance degradation, and ensures grinding operations maintain a stable, efficient thermal environment over the long term. It also enhances grinding efficiency while reducing energy consumption, making it an indispensable technical step for optimizing production and guaranteeing cement quality.

Impact of Thermal Imbalance in Cement Ball Mills

- During grinding, the majority of energy is converted into heat, causing elevated temperatures within the mill. This leads to a series of consequences:

- Degraded cement quality: May trigger gypsum dehydration, inducing false setting in cement and compromising later strength development.

- Equipment Operational Safety: Excessive bearing temperatures threaten equipment integrity and disrupt continuous operation.

- Reduced Grinding Efficiency: Elevated temperatures may exacerbate material “balling” or “clumping,” diminishing grinding effectiveness.

- Downstream Process Issues: High-temperature cement complicates packaging and storage while potentially impairing concrete workability.

- Consequently, conducting thermal balance analysis and implementing cooling measures is critical.

Common Cooling Measures and Thermal Balance Applications

- When mill temperatures are excessively high or thermal balance calculations indicate significant excess heat in the system, the following measures may be considered:

- Internal Water Spraying: This is the most direct and effective internal cooling method. Spraying an appropriate amount of atomized water into the mill utilizes the heat absorption principle of water evaporation to reduce temperatures.

- External Cylinder Cooling: Water spraying on the cylinder exterior for heat dissipation. Though simple, this method yields minimal practical effect and may accelerate cylinder corrosion. It is typically used only as a temporary auxiliary measure.

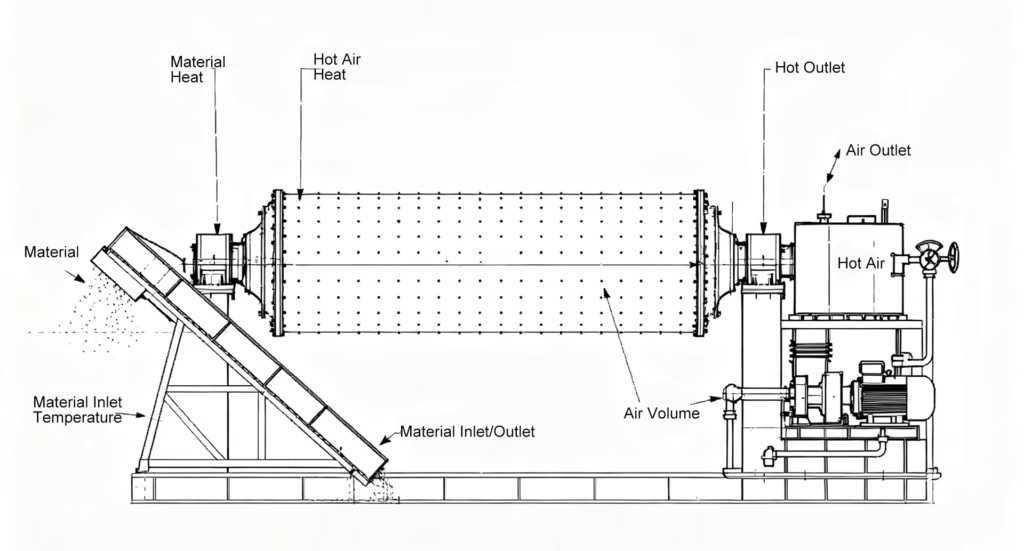

- Internal Mill Ventilation: Optimize ventilation system design (e.g., ductwork, dust collectors) to enhance mill airflow, promptly removing heat and water vapor generated during grinding. Ensure proper sealing and leak prevention.

- Lower material temperature: Cool clinker before grinding or allow it to cool naturally during storage before feeding into the mill.

- Control material particle size: Thoroughly crush materials before feeding into the mill to minimize particle size during grinding, thereby reducing the heat generated.

- Use grinding aids: Certain grinding aids can enhance grinding efficiency while also lowering mill temperatures to some extent.

Conclusion

Chunlei Machinery is one of China’s leading manufacturers of cement ball mills, offering high-quality ball mill equipment.

If you are interested in ball mills or have any inquiries, please contact us—we are available 24 hours a day to address your questions.