Custom-Engineered Wet Pan Mills Packed for Global Delivery

We are proud to announce that a batch of custom-engineered wet pan mill machinery has successfully completed final quality inspection and has been professionally packed for shipment to our overseas clients. These heavy-duty gold grinding mills, manufactured to exact customer specifications, have undergone meticulous preparation to ensure they arrive at their international destinations in perfect condition, ready for immediate installation and operation.

Our team has carefully loaded each customized wet pan mill into reinforced shipping containers using specialized equipment and protective materials. Every unit is secured with heavy-duty straps and surrounded by custom-cut timber framing to prevent movement during transit. Critical components like the grinding wheels, central shafts, and gear systems receive additional protective wrapping to guard against moisture, salt air, and mechanical shocks during the long ocean voyage.

Specialized Design for Specific Mineral Processing Needs

This shipment represents our commitment to providing tailored mineral processing solutions for diverse international mining operations. Each wet pan mill in this consignment has been customized based on detailed client requirements regarding capacity, material specifications, and operational parameters. Our engineering team worked closely with each client to optimize these mills for their specific ore characteristics, whether for gold, silver, or other precious metal recovery.

The custom manufacturing process incorporated specialized features including reinforced frames for high-capacity operation, wear-resistant alloy grinding wheels for extended service life, and adjustable discharge systems to control product fineness. These modifications ensure that each mill will deliver optimal performance in its destination environment, maximizing recovery rates and operational efficiency for our clients’ mining operations.

Prior to packing, every wet pan grinding mill underwent comprehensive testing and quality verification. Our quality control team conducted trial runs with material samples to confirm operational parameters matched design specifications. All mechanical systems, including the central drive, gear transmission, and lubrication systems, received final inspection and testing.

Contact us today! Let us create greater value for your project with our professional expertise and reliable equipment.

Related Products

Impact Crusher

505A variety of models are available | Get the free price list! Impact crushers are categorized into PF impact crushers and CI impact crushers. PF Impact crusher, also called small diameter impact crusher. CI Impact C…

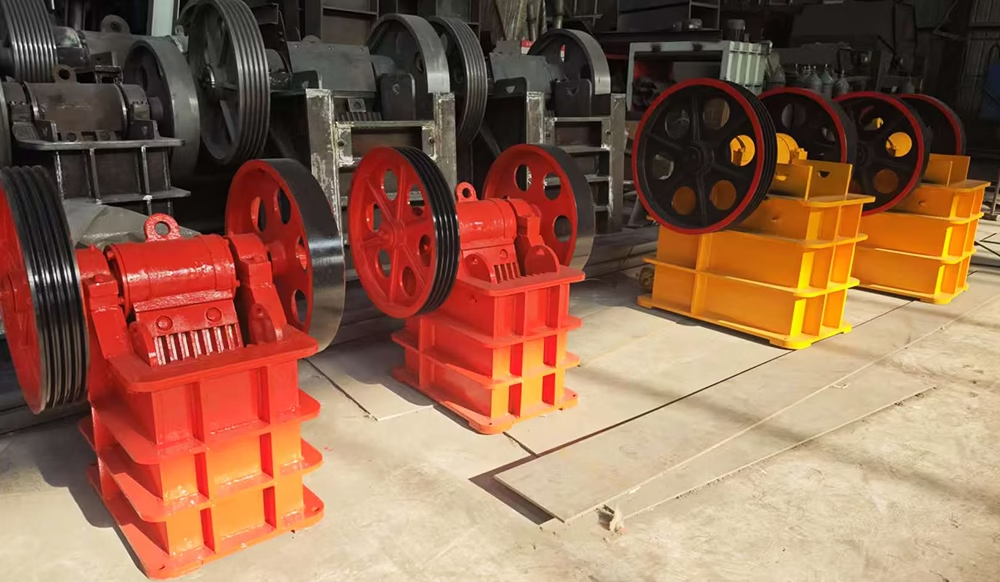

PE/PEX Jaw Crusher

553A variety of models are available | Get the free price list! PE Jaw Crusher, abbreviated as Jaw Crusher, is a kind of mechanical equipment that utilizes jaw plates to crush, rub and grind materials. According to t…

Small Hammer Crusher

506A variety of models are available | Get the free price list! Small hammer crusher is a kind of small hammer crusher, which is mainly used for medium and fine crushing of various materials.Hammer crusher can be use…

Hydraulic Cone Crusher

549A variety of models are available | Get the free price list! Hydraulic Cone Crusher is a new type of cone crusher which is suitable for crushing high hard materials and has strict requirements on product grain sha…

loading…

已经是到最后一篇内容了!

RelatedCases

Chunlei Machinery Jaw Crusher Helps Tanzania Mining Industry Development

Chunlei Machinery Jaw Crusher Helps Tanzania Mining Industry Development In the increasingly competitive global mining equipment market, Chunlei Machinery’s jaw crusher is winning more and more international customers with its excellent per…

Shipped to Vietnam Crushing Production Line

Shipped to Vietnam Crushing Production Line Recently, a set of 500 tons per hour granite crushing production line equipment customized by our company for Vietnam customers was formally shipped. Related Products …

Mechanical Sand Sulfur Gold Ore Gravity Separation – Spiral Chute

Recently, an African client contacted us seeking to concentrate gold and sulfur from sulfur ore. Based on the client’s requirements and existing equipment, and to prevent tailings loss, our engineer recommended the Model 900 spiral chute. After…

220TPH Double Screw Sand Washing Machine Arrives in Saudi Arabia

Recently, our long-time customer in Saudi Arabia once again cooperated with us and ordered an XS2400 double screw sand washing machine with a production capacity of 220 tons per hour. We are very grateful for the trust and support of our Saudi Ar…

loading…

已经是到最后一篇内容了!