Hard rock crushing has long posed a significant challenge in mining operations. Ensuring effective crushing while controlling costs has become an urgent industry priority. Traditional crushing methods often involve high energy consumption and excessive wear. Today, more advanced equipment—the High-Pressure Roller Crusher (HPGR)—has emerged. With its exceptional process performance, it is progressively becoming the preferred choice for hard rock crushing. Operating on the principle of high-pressure laminar crushing, this equipment boosts crushing efficiency while significantly reducing energy consumption and wear costs. It offers a more sustainable and economical production pathway for hard rock processing. Understanding the core advantages of HPGR will empower production operations to achieve superior energy efficiency control and more stable output quality.

What are the primary challenges in hard rock crushing?

As a fundamental process in mining and aggregate industries, hard rock crushing plays a vital role in transforming massive ore bodies into processable materials. However, it has long faced significant challenges, including crushing efficiency, operational costs, and environmental factors. Overcoming these obstacles requires advanced technologies rather than relying solely on traditional crushing methods.

Crushing hard materials typically consumes substantial energy. Traditional equipment like jaw crushers and cone crushers often incur massive electricity consumption when processing high-hardness rock, driving up power costs. Core components such as jaw plates and liner plates in jaw crushers also suffer accelerated wear from tough rock. This not only increases replacement costs but also raises overall operational expenses due to extended downtime. Simultaneously, conventional crushing methods frequently produce substandard particle shapes. The form of such aggregate products directly impacts concrete strength and engineering quality. Dust emissions and noise pollution remain persistent environmental concerns in hard rock crushing. Energy consumption, wear, quality control, and environmental protection—these intertwined challenges make hard rock crushing a systemic endeavor, driving the industry to continually seek more efficient, durable, and intelligent crushing solutions.

High-Pressure Roller Mill: The Hard Rock Specialist

The High-Pressure Roller Mill (HPGR) represents a technological breakthrough in crushing processes. Transcending the limitations of traditional crushing methods, it employs a unique laminar crushing principle to apply extreme pressure between material particles, achieving a transition from “crushing” to “disintegration.” With lower energy consumption, superior particle shape, and higher processing efficiency, it is emerging as the new favorite in hard rock crushing. It delivers not merely equipment upgrades, but a complete revolution in the crushing process and an enhancement of the entire value chain.

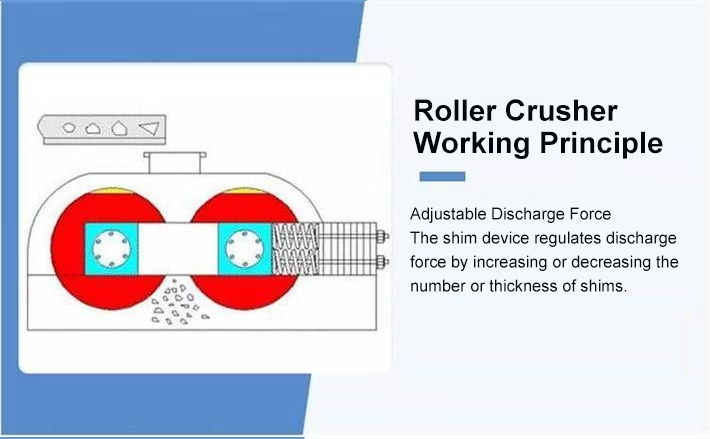

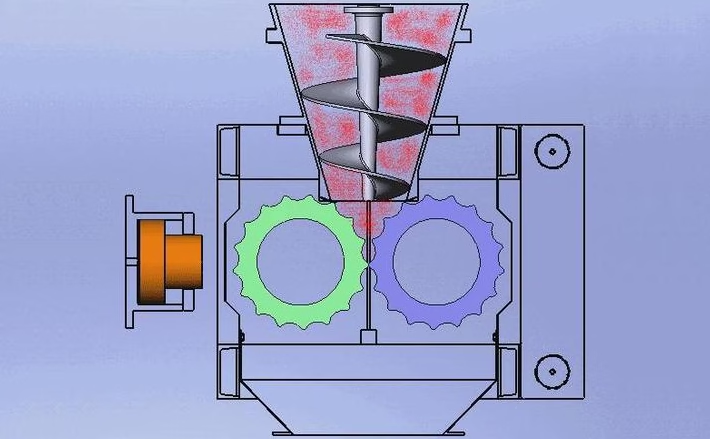

The High-Pressure Roller Crusher (HPGR) employs a unique inter-particle crushing principle. Two counter-rotating rollers exert immense pressure on the material, causing particles to squeeze and fracture against each other within a high-pressure compression zone. In contrast, traditional crushers rely solely on mechanical impact or compression. This laminar crushing method not only boosts grinding efficiency and reduces energy consumption but also produces uniformly sized particles with lower fines content, representing a technological breakthrough in crushing.

How does the high-pressure roller mill crush materials?

The true value of HPGR extends far beyond simple size reduction. Under immense pressure, mineral particles endure high shear forces and compressive stresses. This crushing method generates microscopic cracks invisible to the naked eye within the mineral grains, effectively reducing rock hardness. This is not mere crushing but selective interfacial dissociation between crystal layers. This micron-level network of fissures enhances downstream flotation or leaching processes by facilitating easier chemical agent contact and faster separation.

As HPGR evolves from a “crushing device” into an ‘activator’ that facilitates downstream operations, it boosts the profitability of the entire production line. It not only reduces grinding energy consumption but also increases recovery rates.

What should be considered when installing a high-pressure roller mill?

Deploying a high-pressure grinding roller (HPGR) requires meticulous planning, taking into account site requirements and material properties. This is fundamental to achieving optimal equipment performance. Failure to do so may result in operational issues and reduced profitability.

Before installation, verify these four critical factors:

First, does the material meet specifications?

Determine the hardness and abrasiveness of the material to be crushed. Crucially, assess moisture content and stickiness. Excessively wet or sticky material can cause roller jamming and efficiency loss.

Second, ensure uniform feeding.

Maintain consistent, level material flow during feeding. Irregular feeding causes localized roller wear, reducing crushing efficiency and throughput.

Third, perform regular maintenance.

Although HPGRs exhibit low overall wear rates, gradual wear occurs. Routine inspections are essential to sustain long-term operational efficiency.

Fourth, vibration damping is essential

Unavoidable vibrations occur during crushing operations, necessitating robust vibration control measures. Install equipment on specially designed, sturdy foundations and implement effective vibration isolation. This is crucial for protecting plant structures and ensuring stable operation of surrounding equipment.

Conclusion

In summary, dedicating time to advance planning for material selection, feeding consistency, maintenance protocols, and vibration control is key to ensuring the efficient and stable operation of high-pressure roller crushers.

CHUNLEI Machinery is China’s leading manufacturer of mineral processing equipment, specializing in B2B solutions. Our product line covers the entire process chain: crushing, grinding, beneficiation, screening, and drying. We provide full-cycle support including design, manufacturing, installation, training, and after-sales service. We are committed to delivering high-quality, customized, and efficient solutions to help clients achieve their operational goals.

Contact CHUNLEI today to explore your hard rock crushing needs.