Sand Washing Production Line Sent to Saudi Arabia

In the sand and gravel aggregate processing industry, sand washing equipment is the key link to improve the quality of finished sand. In order to meet customers’ pursuit of efficient sand washing operation, as a professional sand washing equipment manufacturer, we provide core equipment such as silo, XS2400 sand washer, belt conveyor, etc., and ensure efficient delivery to help customers put into production quickly. The core of this production line is equipped with silo, XS2400 sand washing machine and belt conveyor.

Introduction of Core Equipment of Sand Washing Production Line

(1)Silo – the cornerstone of storage and feeding to ensure the continuity of feeding

Silo is the starting link of sand washing production line, used for storing and evenly conveying raw materials. Our silo is made of wear-resistant steel plate with solid structure, which can effectively reduce the problem of material blockage and ensure the continuous operation of the production line.

(2)XS2400 sand washing machine – the core power of washing sand and gravel

XS2400 sand washing machine is the core equipment in the production line, adopting wheel and bucket structure, with strong cleaning capacity and low water consumption, it can effectively remove the soil and impurities in sand and gravel, and improve the purity of finished sand.

(3) Belt Conveyor – Efficient Link for Material Conveying

Belt conveyor is used to connect each production link and realize the automatic transportation of materials. Our conveyor adopts high-strength wear-resistant belt, which is smooth running and easy to maintain, and can significantly reduce the cost of manual handling.

Fast Delivery, Global Supply

We have a mature production system and perfect logistics network, which can ensure fast delivery of sand washing production line equipment:

Domestic customers: 7-15 days delivery, support land transportation, sea transportation and other modes.

Overseas customers: DDP/DDU service, 30-45 days to Hong Kong, assisting customs clearance.

Why choose us?

✅ Reliable equipment quality – made of high quality materials, durable

✅ Customized solution – configure the production line according to customer’s needs

✅ After-sales guarantee – professional team provides installation and commissioning and maintenance support

If you are looking for sand washing production line equipment suppliers, welcome to contact us for the latest quotation and program!

As a backbone enterprise in China’s mining machinery manufacturing field, Chunlei Machinery, since its establishment, has always focused on the research, development and manufacturing of crushing and screening equipment. Headquartered in Zhengzhou, Henan Province, the company has a modern production base covering an area of 20,000 square meters, with an annual production capacity of more than 2,000 sets of various types of crushing equipment. Chunlei Machinery has become an important force in China’s mining machinery export, and its products are exported to more than 30 countries and regions such as Southeast Asia, Africa and South America.

Related Products

Hydraulic Roll Crusher

432A variety of models are available | Get the free price list! Double Roll Crushers are extensively utilized in the mining industry due to their numerous benefits, including high throughput, compact design, low power c…

Combination Crusher

430A variety of models are available | Get the free price list! This series of crushers is a new product optimized and designed based on our company’s PEL vertical compound crusher and combined with domestic and foreign…

Fine Sand Recycling Machine

457A variety of models are available | Get the free price list! Fine sand recycling machine is for slurry material dewatering, de-mediation, desludging development of equipment, through the slurry pump will be the co…

Screw Sand Washing Machine

480A variety of models are available | Get the free price list! Spiral sand washer is a generation of sand washing machine designed for sand and gravel washing and grading and dewatering, its special working principl…

loading…

已经是到最后一篇内容了!

RelatedCases

Shipped to Vietnam Crushing Production Line

Shipped to Vietnam Crushing Production Line Recently, a set of 500 tons per hour granite crushing production line equipment customized by our company for Vietnam customers was formally shipped. Related Products …

50T/H Magnetite Ore Magnetic Separation Process Production Line In Chile

50T/H Magnetite Ore Magnetic Separation Process Production Line In Chile In November, our magnetite magnetic separation process production line was installed in Chile. Under the guidance of professional engineers, the installation was compl…

Shaking Table Model 6S Shipped To Indonesia Customer

Shaking Table Model 6S Shipped To Indonesia Customer Indonesia is a country rich in mineral resources due to its complex geological structure, and the development of galena resources is getting more and more attention from the global mining…

Chunlei Machinery Jaw Crusher Helps Tanzania Mining Industry Development

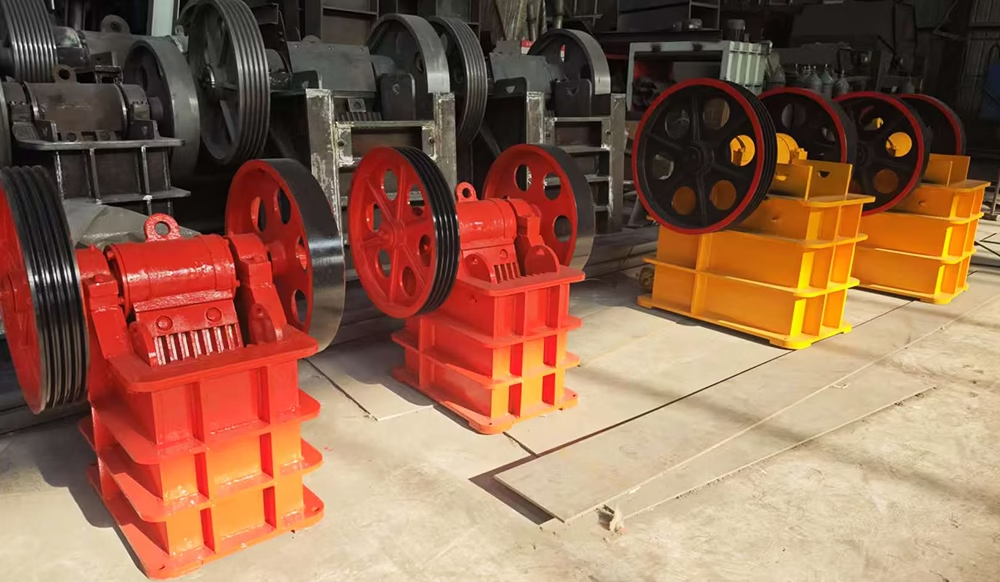

Chunlei Machinery Jaw Crusher Helps Tanzania Mining Industry Development In the increasingly competitive global mining equipment market, Chunlei Machinery’s jaw crusher is winning more and more international customers with its excellent per…

loading…

已经是到最后一篇内容了!