1300 Gold Mill and 30 Centrifuge High Efficiency Gold Beneficiation Solution

Under the background of global gold demand continues to rise, the emerging mining areas in Africa are becoming an important growth point of the international gold industry, and at the same time, efficient equipment is the key to improve the production capacity and revenue. Recently, we have successfully helped a customer in Somaliland to realize a leap in gold beneficiation efficiency, from the principle of equipment configuration to the actual production data, from operation training to after-sales service, through the provision of 1300 models of gold mills and 30 models of centrifuges, which has brought them significant economic benefits.

The customer’s challenge

Somaliland is rich in gold resources, but the client faces the challenge of outdated technology and equipment in gold mining. Traditional artisanal gold panning methods were unable to effectively process complex gold ores, resulting in low gold recovery rates, high production costs, and hazardous working environments with frequent accidents.

The Somaliland region is characterized by relatively weak infrastructure conditions, an unstable power supply and a lack of skilled personnel. These factors determine that the introduced equipment must be strongly adaptable and easy to operate. It is against this background that our 1300 gold mill and 30 centrifuge combination solution was developed, which perfectly fits the actual needs of the local mines.

Molybdenum Deposit

Molybdenum Ore

Pyromolybdenite

Solution: 1300 Gold Mill and 30 Centrifuge

Gold Mill 1300: Efficient Crushing And Grinding

Designed for gold processing, this gold mill offers powerful crushing and grinding capabilities. It has a double wheel drive design with two 1300mm diameter, high strength alloy wheels weighing over 3 tons. This unique structure enables it to efficiently process all types of gold ores with hardnesses ranging from 5-7 on the Mohs scale, and is particularly suitable for gold-bearing quartz veins and altered rock ores in Somaliland. 1300 Gold Mills are made of high-strength steel, durable, and of modular design, which is easy to be installed and adapted to the harsh working environment.

Model 30 Centrifuge: High Precision Gravity Separation

As one of the core equipments in the gold separation process, Model 30 centrifuge adopts the advanced centrifugal gravity separation principle, utilizing the strong centrifugal force generated by high-speed rotation, which can accurately separate the gold in the gold ore from other impurities. 30 centrifuges have a particularly remarkable effect on the recovery of gold associated with Somaliland lapis lazuli ore. The centrifuge has a very high separation efficiency, which significantly improves gold recovery. The high throughput of the centrifuge is perfectly matched to the 1300 Gold Mill, which greatly enhances the overall capacity of the processing line. In addition, the Model 30 centrifuge is easy to operate and low-maintenance, saving the customer significant labor and material resources.

Customer Testimonials

Customers have nothing but praise for our 1300 Gold Mill and 30 Centrifuge. They say, “The combination of the Model 1300 Gold Mill and Model 30 Centrifuge has completely changed our production model. What used to take 20 people a week can now be accomplished by three people in a day, and the amount of gold recovered has nearly doubled.

This system is simply a revolutionary improvement for a medium grade gold mine like ours.”If you are facing similar challenges in gold processing, our 1300 model gold mill and 30 model centrifuge are the best choice for you.

The customer particularly appreciates the equipment’s durability and adaptability: “In the hot and dusty environment of Somaliland, the equipment has been running continuously for three months without major failures and with only routine lubrication maintenance. Even in the face of fluctuations in the nature of our ore, stable operation is maintained by simple parameter adjustments.”

Our professional team can provide you with a full range of solutions, from equipment selection, installation and commissioning to after-sales maintenance, one-stop service to make you worry-free. Contact us now to start your journey of efficient mineral processing!

Customize Your Solutions

Contact us now via email: info@miningmachinerys.com, or WhatsApp me, or fill in the form below.

Contact Us

If you need to know more product information

Submit your product intentions and needs, we will contact you in the first time!

RelatedCases

High-efficiency Environmental Protection Mobile Crushing Plant Delivery

High-efficiency Environmental Protection Mobile Crushing Plant Delivery With the increase of urban renewal projects, a construction company is facing a large amount of construction waste disposal problems, and the traditional fixed crushing…

Shaking Table Model 6S Shipped To Indonesia Customer

Shaking Table Model 6S Shipped To Indonesia Customer Indonesia is a country rich in mineral resources due to its complex geological structure, and the development of galena resources is getting more and more attention from the global mining…

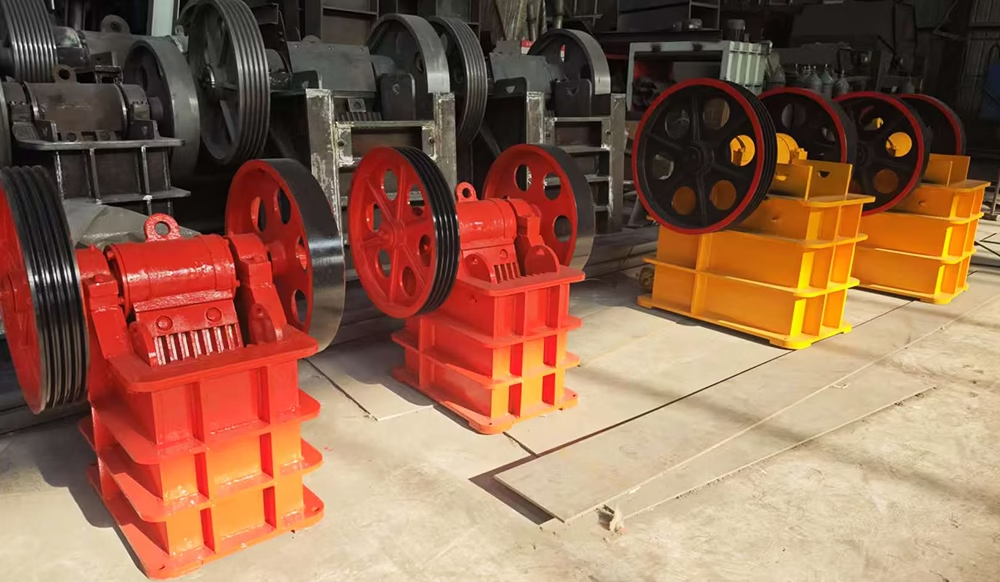

Chunlei Machinery Jaw Crusher Helps Tanzania Mining Industry Development

Chunlei Machinery Jaw Crusher Helps Tanzania Mining Industry Development In the increasingly competitive global mining equipment market, Chunlei Machinery’s jaw crusher is winning more and more international customers with its excellent per…

10000T/D Molybdenum Ore Beneficiation Production Line in Bulgaria

10000T/D Molybdenum Ore Beneficiation Production Line in Bulgaria A molybdenum mine in Bulgaria, the metal minerals in the ore are mainly pyrite and molybdenite, and the vein minerals are mainly quartz, the nature of the ore is relatively h…

loading…

已经是到最后一篇内容了!

Chunlei Mining Machinery

Chunlei Mining Machinery