This article provides a comprehensive analysis of stone crushing plants, covering their definition, types, core equipment, and operational processes. We hope to assist you in developing efficient solutions for your current or future projects.

What is a Stone Crushing Plant?

A stone crushing plant, also known as a stone crushing production line or aggregate production plant, is a production line engineering project composed of crushing equipment, screening equipment, conveying equipment, and other components. Its primary function is to transform large rock into finished sand and gravel of various particle sizes through coordinated equipment operations. This achieves a transformation “from large to small, from coarse to fine,” supplying high-quality raw materials for concrete, asphalt, roadbeds, and other applications. Typical processed materials include limestone, granite, river pebbles, and basalt.

Types of Stone Crushing Plants

Both stationary and mobile crushing plants are commonly used equipment today.

Stationary crushing plants require foundation installation at a fixed site. Designed for large-scale, continuous production, they can achieve hourly outputs exceeding 1,000 tons with stable operation, making them the preferred choice for large-scale mines and infrastructure projects.

Mobile crushing plants integrate feeding, crushing, and screening equipment onto one or more mobile truck chassis. Requiring no complex foundation work, they can rapidly commence operations upon arrival at the site. Available in tire-mounted and track-mounted configurations, they are suitable for small-to-medium-sized projects, short-term operations, or projects requiring frequent relocation.

Key Equipment and Process

Vibrating Feeder: Responsible for uniformly and continuously feeding rocks from the raw material silo into the primary crusher.

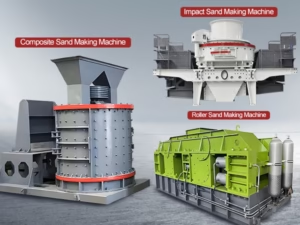

Crushing System: Comprising a jaw crusher for primary crushing and a cone crusher or impact crusher for secondary and tertiary crushing. This stage is the most critical component of the entire project.

Vibrating Screen: Classifies the crushed aggregate mixture by particle size. Oversized particles that fail to meet specifications are returned to the crushing system for reprocessing.

Belt Conveyor: Connects all equipment like a bridge, ensuring the seamless transfer of materials throughout the process.

How to Choose the Right Stone Crusher Manufacturer?

Selecting a reliable stone crusher manufacturer is crucial. You need to consider raw material properties, production capacity requirements, finished product specifications, investment budget and site conditions, as well as the supplier’s capabilities.

As a professional mining machinery manufacturer, CHUNLEI offers EPC turnkey services (Design-Manufacturing-Installation-Commissioning), dedicated to providing customized, high-efficiency, low-energy-consumption comprehensive solutions for stone crushing plants. From scheme design to equipment production, installation commissioning, and after-sales support, we deliver one-stop services to ensure your investment project achieves maximum returns. Contact us now for a free customized solution quote!