Gold Mine CIP – Carbon in pulp Process

CIP Introduction

Gold CIP (Carbon in Pulp) is a non-filtered cyanide carbon slurry process that recovers gold from cyanide slurry through activated carbon adsorption. Gold CIP is the ideal choice for processing oxidized gold ores with low sulfur content and high clay content. CHUNLEI is a supplier of customized gold CIP processing equipment designed to efficiently address these challenges.

What is Gold CIP?

Gold CIP (Carbon-in-Pulp) is a gold extraction technology primarily comprising cyanide leaching, activated carbon adsorption, desorption, and carbon regeneration. Whole ore cyanidation leaches gold from crushed ore, followed by direct adsorption and recovery of gold from the cyanide pulp using activated carbon. This method is widely adopted due to its high cost-effectiveness and recovery rates.

The CIP process is primarily suitable for two types of ores:

- Flotation gold concentrates or amalgam/gravity separation tailings;

- Oxidized muddy ores, particularly those with high clay content and poor filterability.

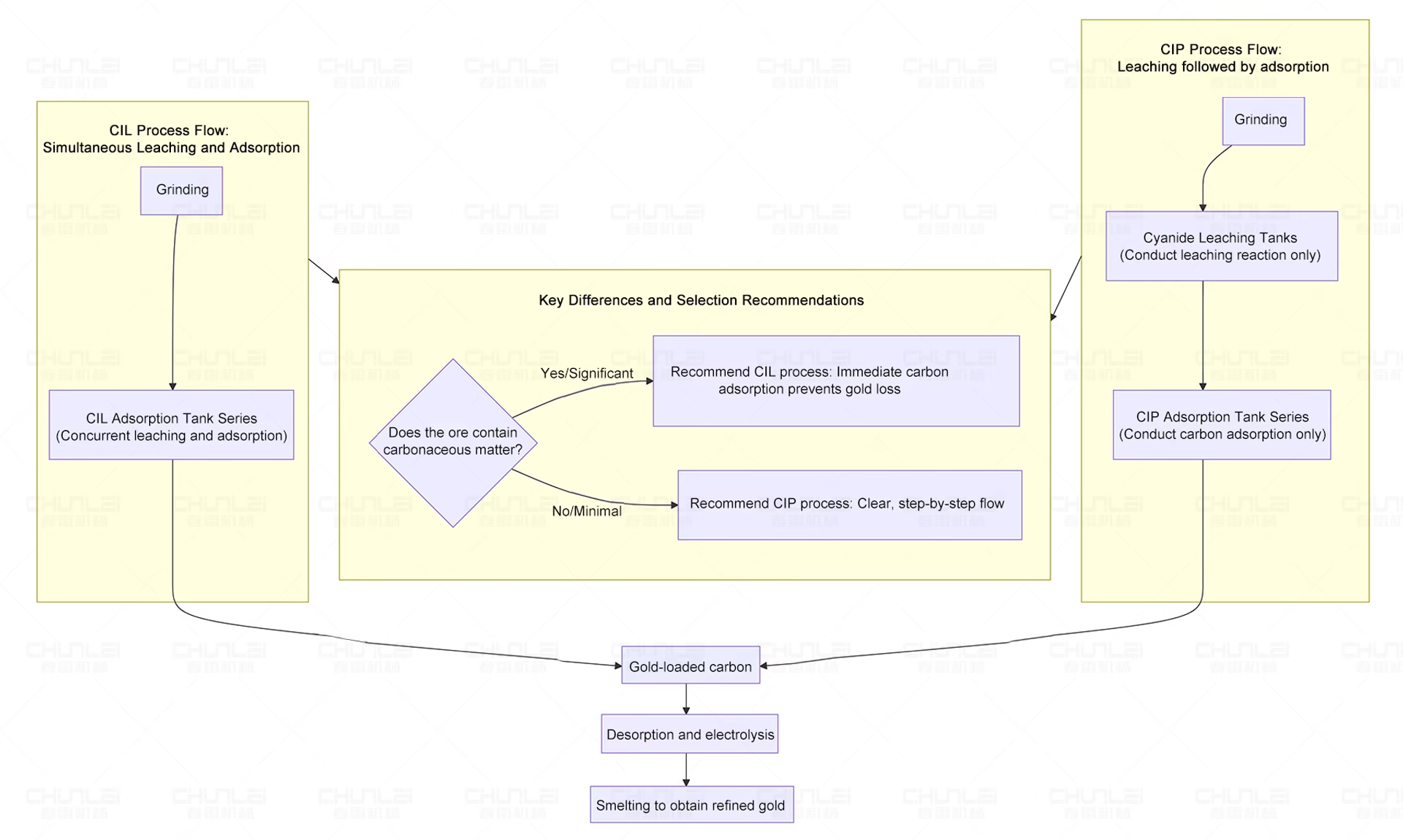

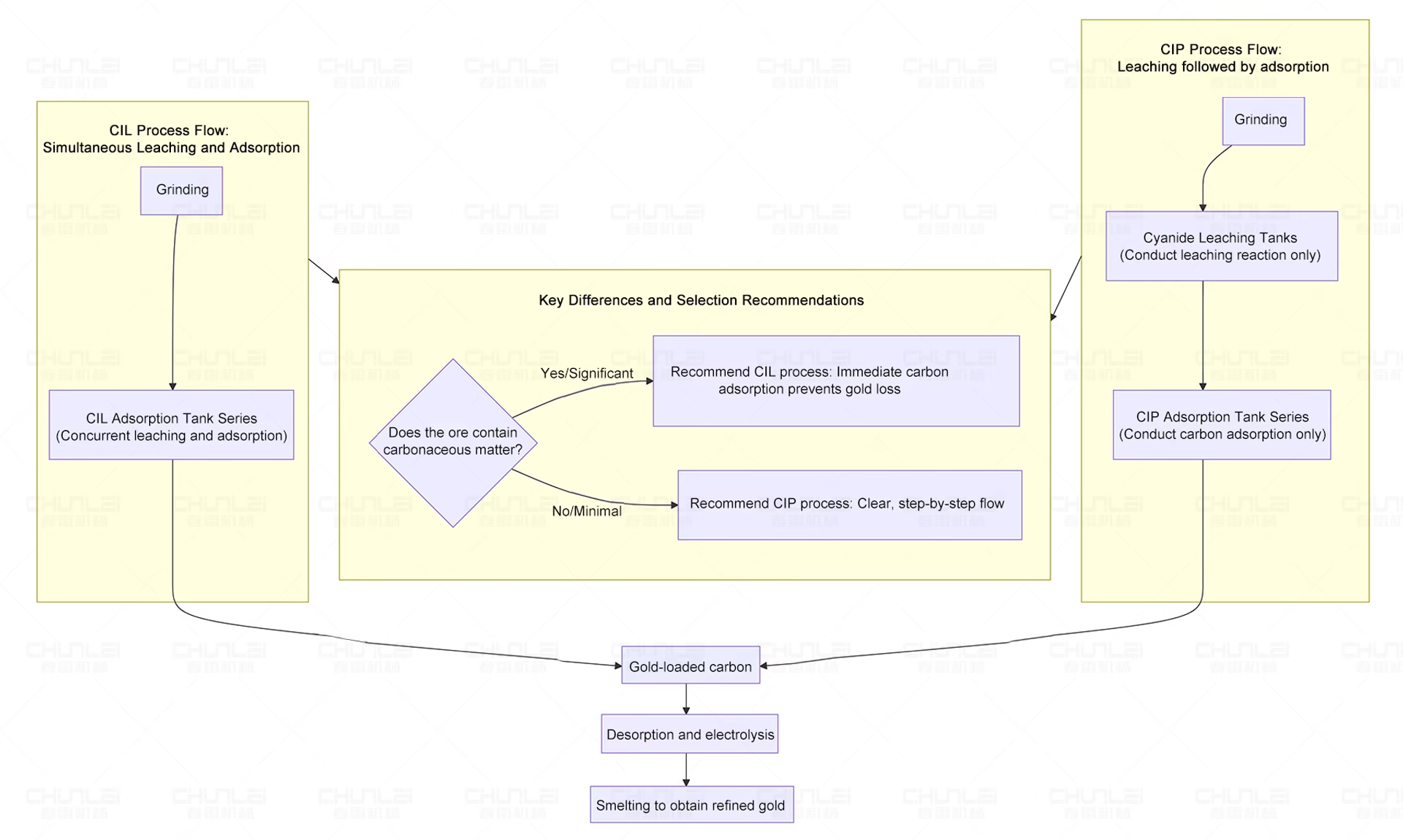

Differences Between Gold CIP and CIL

In the CIP process, leaching precedes adsorption. Gold leaching typically occurs first in dedicated tanks, followed by adsorption in separate tanks where activated carbon is introduced. Cyanide leaching and carbon adsorption are two independent, sequential steps. This process is suitable for simple, easily leachable ores or those with low carbon content.

In the CIL process, leaching and adsorption occur simultaneously within the same tank. This is particularly suitable for gold ores that inherently contain carbonaceous material.

Compared to the Merrill-Crowe process (zinc precipitation method), CIP/CIL processes are generally more effective for low-grade ores and those with higher silver or copper content, as carbon exhibits greater selectivity for gold.

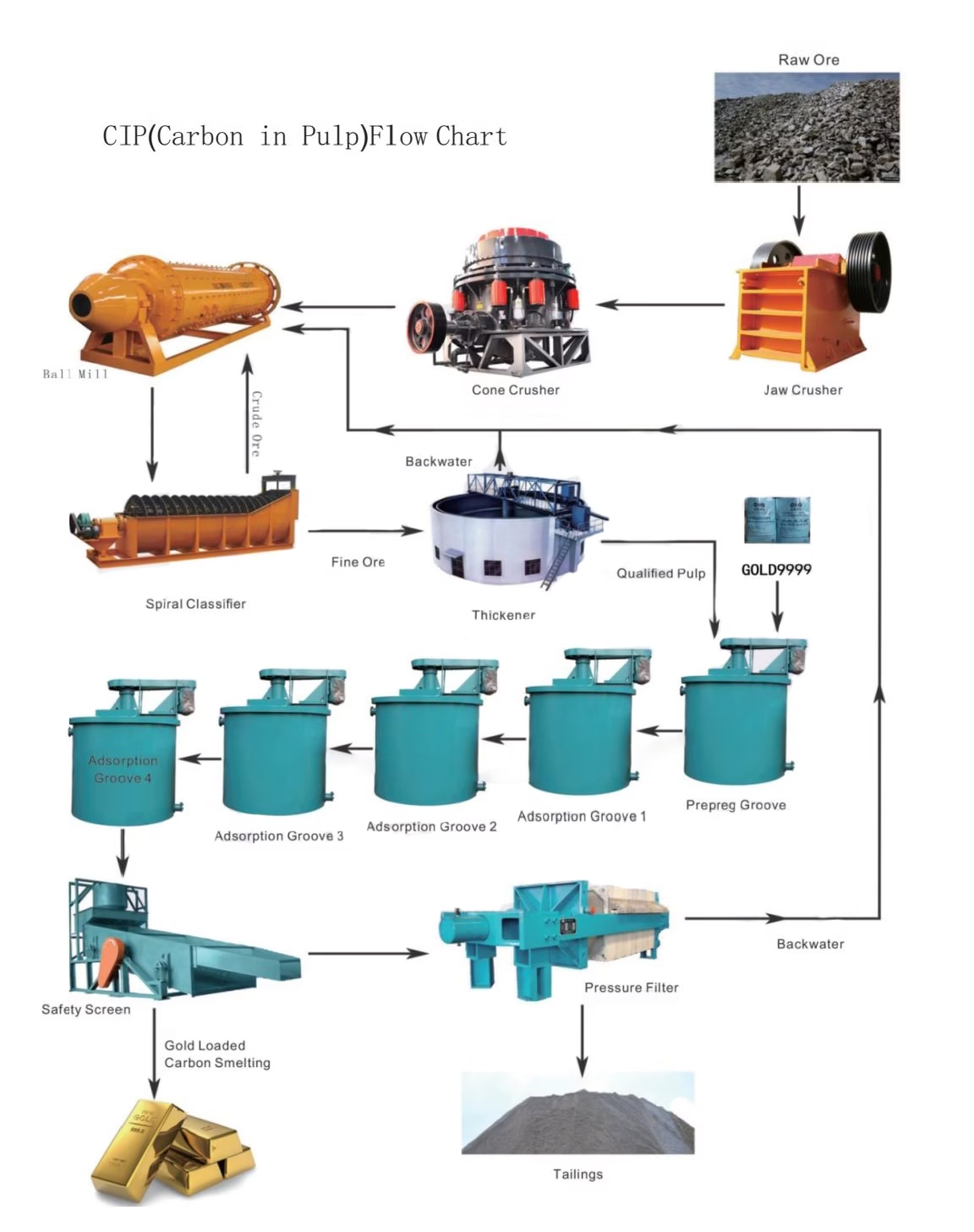

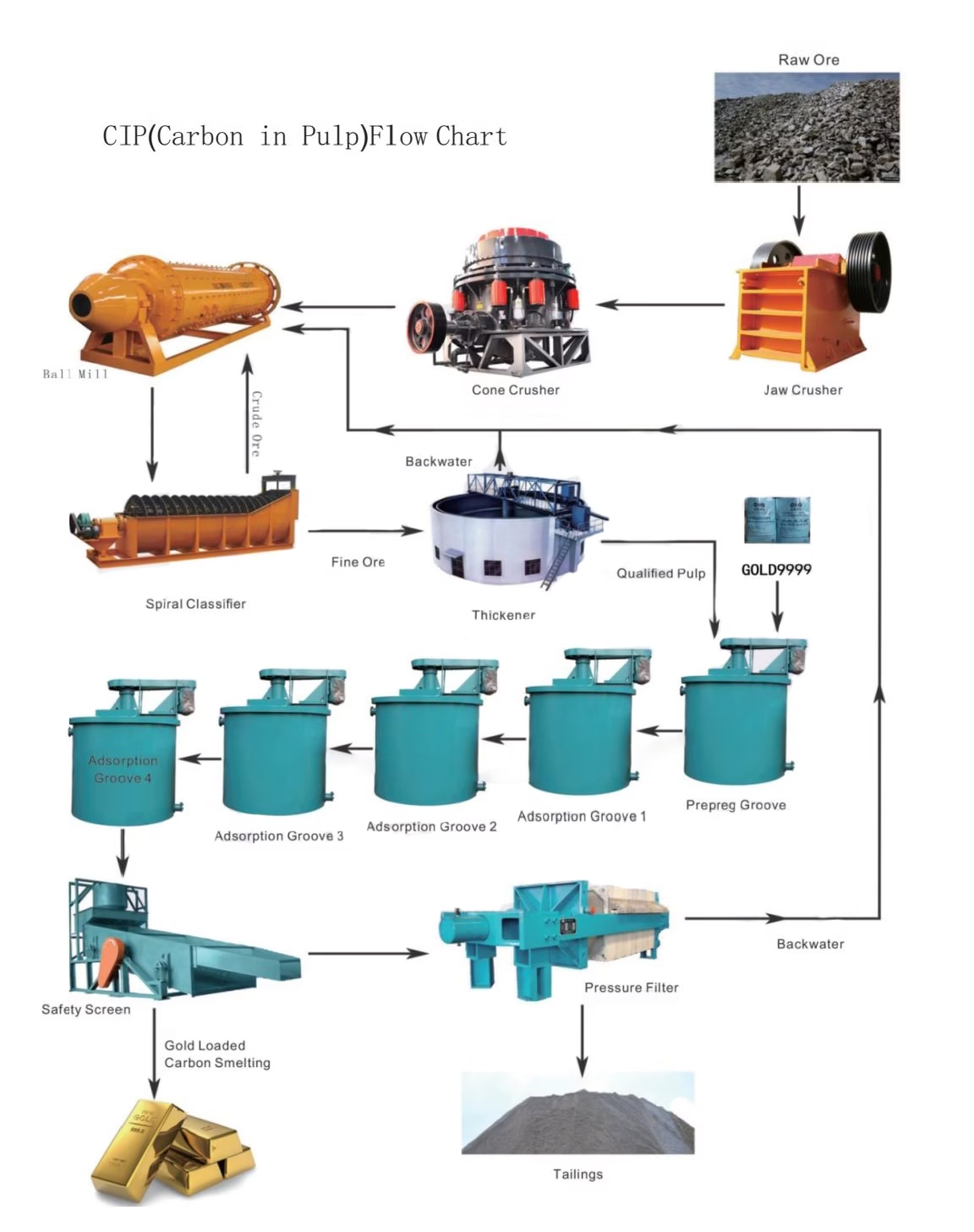

Complete Gold CIP Process Flow

The CIP carbon-in-pulp process comprises seven key stages:

- Crushing and Grinding

Gold-bearing ore is crushed and ground using equipment such as jaw crushers and ball mills to achieve a particle size suitable for cyanidation. This thoroughly liberates gold minerals and removes impurities to prevent gold loss. - Cyanide Leaching

Sodium cyanide (or potassium cyanide) solution is added to agitated tanks, reacting with gold to form soluble cyanide-gold complexes. Leaching duration is adjusted based on ore properties. - Activated Carbon Adsorption

This core CIP step occurs in tandem adsorption tanks post-leaching. Activated carbon is added to leach tanks, where countercurrent adsorption recovers gold. Vibrating screens then separate carbon from the pulp. - Gold Desorption from Activated Carbon

This step “releases” gold from the activated carbon. Gold-loaded carbon is removed from the adsorption tank, washed, and fed into dedicated desorption columns where high-temperature desorption occurs. - Electrolytic Deposition

This step extracts gold from the liquid phase, converting it into a solid. The eluate (with gold grades reaching 600 g/m³) enters an electrolytic cell where an electric current causes gold to deposit, forming gold slime. Electrolytic deposition achieves recovery rates exceeding 99.5%. - Activated Carbon Regeneration

The desorbed carbon (termed depleted carbon) exhibits reduced activity due to surface impurities and requires regeneration for reuse. It undergoes acid washing with dilute hydrochloric acid followed by calcination at approximately 750°C for about 30 minutes.

Once reactivated, it can be recycled. - Tailings Treatment

The slurry discharged from the final adsorption tank (tailings) contains trace amounts of cyanide. It must undergo environmental treatment to meet discharge standards, preventing pollution.

The CIP carbon-in-pulp process forms a meticulously designed closed-loop system. Through its core countercurrent adsorption design, it achieves highly efficient and economical gold recovery, establishing itself as an indispensable mainstream technology in modern gold extraction.

Role of Activated Carbon in Gold CIP Process

Activated carbon is indispensable in gold CIP processes. While its raw materials are diverse, coconut shell carbon is renowned for its highly developed microporous structure, making it the preferred choice for CIP applications. The entire process primarily involves two major steps: carbonization and activation.

Step 1: Carbonization

Carbonization involves heating raw materials in an oxygen-deficient or oxygen-free environment to 400-700°C. This removes volatile substances (such as water vapor, hydrocarbons, and tar) from the raw material, forming an initial pore structure to produce “carbonized material.” At this stage, the material possesses preliminary adsorption capacity, but its pores are prone to clogging and require further processing.

Step 2: Activation

Activation is the core process determining activated carbon’s final adsorption performance. It involves two methods: physical and chemical activation.

- Physical Activation: The carbonized material reacts with oxidizing gases (e.g., steam, carbon dioxide) at 800-1100°C to remove some carbon atoms, thereby cleaning and enlarging pores formed during carbonization. This process is relatively environmentally friendly but consumes high energy.

- Chemical Impregnation Method: The raw material is mixed with chemicals and impregnated. At temperatures between 450-900°C, tar formation is suppressed while corrosion and pore formation occur. This method is highly efficient and low in energy consumption but may cause equipment corrosion and environmental pollution.

CHUNLEI highlights a frequently overlooked step here—carbon testing. In gold mines employing the carbon-in-pulp (CIP) process, prolonged operation inevitably leads to activated carbon degradation. Therefore, regular carbon inspection is a critical step. It involves testing and analyzing the gold content, distribution, pore structure, and contaminants within the activated carbon used in the process to optimize production and minimize gold loss. Carbon inspection makes the CIP adsorption process efficient and controllable, serving as a vital component in gold recovery.

Advantageous features of Gold Mine CIP Carbon-in-pulp

- High adsorption rate and high recovery rate: Activated carbon has high adsorption capacity and can effectively recover gold from slurry.

- No filtration step: The CIP process eliminates the expensive solid-liquid separation process, simplifies the process and reduces production costs.

- Optimize production links: By optimizing each production link, production efficiency is improved.

- Suitable for complex ores: The CIP process is particularly suitable for ores that have undergone complex smelting reactions, and can significantly improve production efficiency and reduce chemical and electricity consumption.

In short, the CIP carbon slurry method is an efficient and economical gold extraction process and is widely used in the gold mining industry.

Core Equipment and Maintenance of the Gold CIP Plant

The CIP process primarily encompasses the following operational stages: leaching pulp preparation, cyanide leaching, activated carbon adsorption, gold-loaded carbon desorption, electrolytic gold sludge production, gold-stripped carbon recycling, and pulp treatment. Core equipment is distributed across these production segments:

| Processing Stages | Core Equipment | Primary Functions and Characteristics |

| Ore Pre-treatment | Jaw Crusher, Ultra-Fine Laminar Self-Grinding Mill, Ball Mill | Crush and grind ore to the target particle size (typically requiring 60-70% passing -200 mesh), ensuring thorough liberation of gold minerals to prepare for cyanide leaching. |

| Leaching and Adsorption | Leaching Agitator Tank, Carbon Separation Screen (Carbon Recovery Screen) | Leaching Tanks: Thoroughly mix cyanide solution with pulp to dissolve gold. Carbon Separation Screen: Separate activated carbon from pulp to prevent carbon loss. |

| Gold-Bearing Carbon Processing | High-Efficiency Low-Consumption Rapid Desorption Electrolysis System | Under high temperature (up to 150°C) and high pressure (up to 0.5 MPa) in a sealed, cyanide-free environment, gold is desorbed from gold-loaded carbon and electrolytically converted into gold slime, achieving a desorption rate exceeding 96%. |

| Auxiliary Systems | Slurry Impurity Removal Unit | Removes impurities such as wood chips from the pulp prior to adsorption to prevent gold adsorption, contamination of carbon-rich material, or clogging of the carbon separator screen. |

Crushing and Grinding Equipment:

Regularly inspect the wear condition of jaw crusher jaw plates; monitor ball mill liner wear and lubrication systems to ensure stable grinding fineness.

Leaching and Adsorption System:

- Leaching Agitator Tanks:Regularly inspect agitator blade corrosion and wear to maintain agitation intensity and prevent mineral sedimentation.

- Carbon Retention Screen: This is a maintenance priority. Regularly clean the screen mesh to prevent clogging and inspect for damage to avoid loss of activated carbon and gold.

Desorption Electrolysis System: This is the heart of the plant, demanding the highest maintenance standards.

- Regularly inspect pressure-resistant components and seals to ensure no leakage under high temperature and pressure.

- Calibrate control systems for temperature, pressure, liquid level, etc., to guarantee stable desorption process parameters.

- Regularly clean and replace the electrodes in the electrolysis system.

Activated Carbon Management:

- Carbon Loss Control: Activated carbon undergoes wear and consumption during circulation. Fine carbon particles must be effectively recovered via the carbon separator screen, with regular replenishment of new carbon.

- Carbon Regeneration: Depleted carbon after desorption requires activation in a high-temperature regeneration kiln to restore its adsorption activity. Regeneration temperature and atmosphere must be strictly controlled to prevent carbon burn-off.

Key Process Parameters for CIP Carbon Pulp Method

| Process Stage | Core Parameters | Optimization Objectives |

| Grinding Fineness | – 200 mesh particle size: 60–70% | Complete gold dissociation |

| Cyanide Leaching | NaCN concentration: 800 g/t, time: 48 hours | Maximize gold dissolution |

| Carbon Adsorption | Base carbon density: 12 g/L, carbon particle size: 1.43–2.8 mm | Improve adsorption rate, reduce carbon loss |

| Desorption Electrolysis | Temperature: 150°C, pressure: 0.5 MPa, time: 12 hours | Desorption rate >96% |

| Carbon Regeneration | Temperature: 923–973 K, time: 30 minutes | Restore carbon activity |

How To Choose The Right Gold Mine CIP Carbon-in-pulp For Sale

Choosing the right Gold Mine CIP Carbon-in-pulp requires careful consideration of several key factors. This is a guide to help you understand how Gold Mine CIP Carbon-in-pulp works.

Understanding your project needs

Begin by assessing the specific needs of your project. Consider the size of the beneficiation, the climate of the location and the type of material required. Different projects require different production levels, mixing accuracy and environmental standards. Be sure to thoroughly evaluate these factors before making a decision.

Considering equipment output

Plant capacity is critical. Match the capacity of the equipment to your project schedule. For large projects, choose a high-output model to meet demand. For smaller or segmented projects, a mid-sized or small plant may be more appropriate.

Focus on environmental factors

As environmental regulations continue to tighten, it is vital that plants are eco-friendly. Choose equipment with advanced environmental features, such as low-noise design. This not only ensures compliance, but also enhances your company’s image.

Prioritize stability and ease of operation

Stability and ease of operation have a direct impact on efficiency and cost. Choose a plant with automated control systems to minimize human error and increase productivity. Also, consider maintenance costs and the lifespan of key components to ensure consistent performance over time.

Evaluating after-sales service and technical support

Reliable after-sales service and timely technical support are critical. Good support can solve problems quickly, minimize downtime and keep your project on track.

Plan your budget wisely

While the initial investment in mineral processing can be high, choosing durable, stable equipment will provide better returns in the long run. So it’s important to consider not only the purchase price, but also the operating costs, maintenance costs and potential environmental impact.

By taking these factors into consideration, you can find the beneficiation line that best suits your project’s needs, ensuring smooth operation and maximizing your investment.

What Projects Gold Mine CIP Carbon-in-pulp Can Be Used in?

What are the different uses of Gold Mine CIP Carbon-in-pulp? Here are a few items that are often used gold ore flotation production line for sale, highlighting their unique features. When choosing a Gold Mine CIP Carbon-in-pulp, consider factors such as the temperature of the material and climate, not just the application area.

Separation of useful minerals from chalcopyrite minerals for mineral processing and purification

Through various beneficiation methods, such as re-election, flotation, magnetic separation, etc., the useful minerals are separated and the grade of the minerals is improved.

For example, in iron ore beneficiation, the iron-bearing minerals are separated from the quartz and other veinstones to obtain a high-grade iron ore concentrate.

For non-ferrous metal ores, impurities can be effectively removed to provide high-quality raw materials for the subsequent smelting process.

Recovery of valuable elements

Many ores contain a variety of valuable elements, and the beneficiation production line can recover these elements separately.

Tailings Re-election

The tailings produced in the beneficiation process usually contain a certain amount of useful minerals, and the beneficiation production line can re-elect the tailings to recover the residual value.For example, in the gold mine tailings re-election, the use of flotation technology can recover some of the residual gold minerals and improve the total recovery rate of gold.

The beneficiation production line can be adapted to the needs of different industries, such as metallurgical industry, chemical industry, building materials industry and so on.

Metallurgical industry

Provide high-grade raw materials for iron and steel, non-ferrous metal smelting.

Chemical industry

To provide specific quality mineral raw materials for chemical production

Building Material industry

Provide mineral raw materials for building materials.

What can ChunLei do for you-about service?

Pre-sales service

1. Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

In-sales service

1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

After-sales service

1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

The CIP carbon-in-pulp process for gold mining has emerged as one of the core techniques in modern gold extraction due to its unique advantages of high efficiency, cost-effectiveness, and environmental sustainability.

For further inquiries regarding equipment selection or technical optimization of CIP processes, please consult CHUNLEI’s professional mining technology team to obtain customized solutions!

You may also want to know about Gold Mine CIP Carbon-in-pulp Production Line-FAQ

1. What is the fundamental principle of the CIP carbon-in-pulp process for gold mining?

It involves the selective adsorption and recovery of gold using activated carbon particles directly from gold-bearing oxidized solutions (typically cyanide-leached pulp), thereby achieving the separation and enrichment of gold from solid impurities in the pulp.

2.What is the difference between the carbon-in-pulp (CIP) method and the carbon-in-leach (CIL) method?

CIP: Leaching occurs first, followed by adsorption. The leaching tank and adsorption tank are separate.

CIL: Leaching and adsorption occur simultaneously within the same series of tanks. That is, while cyanide dissolves the gold, activated carbon adsorbs the dissolved gold.

3.What type of gold ore is suitable for processing using a CIP carbon-in-pulp production line?

The most critical characteristic of gold ore suitable for CIP carbon-in-pulp processing is that the gold must exist in a “free” or “exposed” fine-grained state, capable of being dissolved by a cyanide solution (leaching agent) and effectively adsorbed by activated carbon.

4. Is the investment cost for building a CIP carbon black plant high? How much does it roughly cost?

The investment cost for a CIP carbon black plant primarily includes equipment procurement, infrastructure construction, installation engineering, and working capital. The actual investment amount depends on the specific implementation plan.

5. What are the common malfunctions in CIP production lines during operation? How can they be troubleshot?

Malfunctions in CIP (carbon-in-pulp) production lines directly impact production metrics and economic efficiency. The most frequent issues include reduced gold adsorption rates, excessive activated carbon consumption, and intermediate screen blockages. For specific problems, contact Chunlei customer service for one-on-one solutions.

REQUEST A QUOTE

If you need to know more product information

Submit your product intentions and needs, we will contact you in the first time!