Impact Crusher

518A variety of models are available | Get the free price list! Impact crushers are categorized into PF impact crushers and CI impact crushers. PF Impact crusher, also called small diameter impact crusher. CI Impact C...

View detailsSearch the whole station Hot Product Catalog

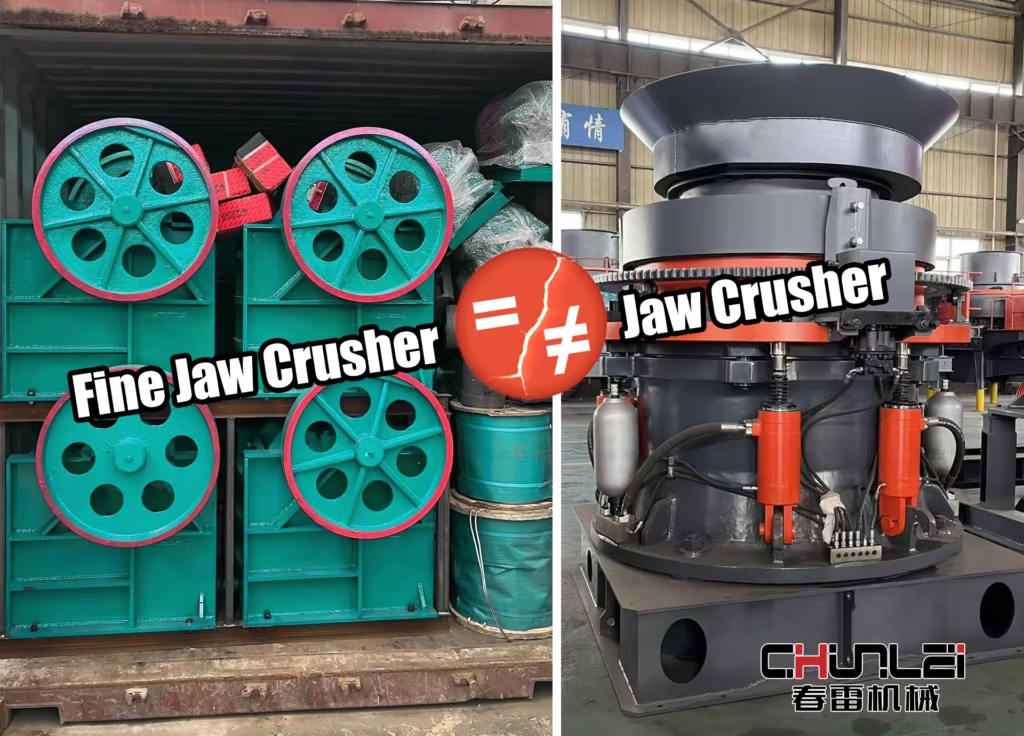

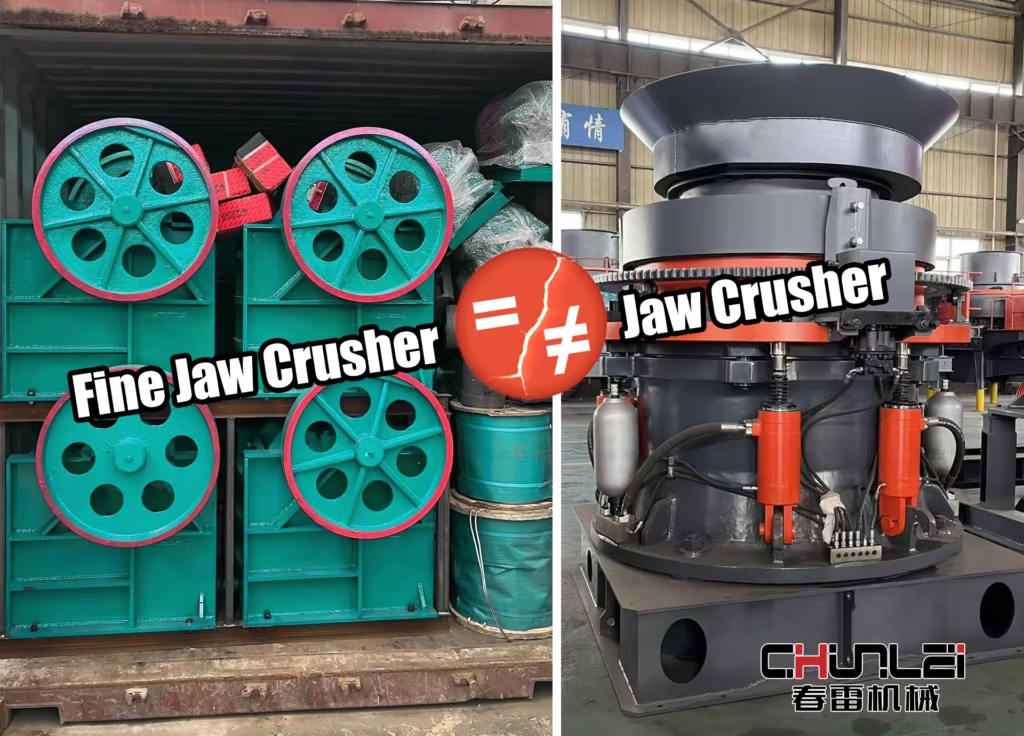

To be precise, a “fine jaw crusher” is a specific type of “Jaw Crusher.” Jaw crushers constitute a broad category, primarily divided into two main types based on their output particle size and application:

Primary Jaw Crusher: This is the most common, traditional “jaw crusher.” It primarily serves the primary crushing (coarse crushing) stage in production lines. Featuring a large feed opening, it can handle exceptionally large rocks (up to 1 meter or more). Its discharge particle size is relatively coarse, typically around 150-350mm.

Fine Jaw Crusher (abbreviated as “Fine Jaw Crusher”): This jaw crusher is specifically designed for medium or fine crushing. It is typically paired with cone crushers or impact crushers for medium and fine crushing stages. While sharing the same structural principle as the coarse jaw crusher, its design is optimized to produce finer output material.

For a clearer understanding, the table below compares their critical distinctions:

| Characteristic | Primary Jaw Crusher (Standard Jaw Crusher) | Secondary Jaw Crusher (Fine Jaw Crusher) |

| Primary Application | Primary crushing (first stage) | Medium and fine crushing (Secondary and tertiary crushing) |

| Feed Size | Large (typically up to 500mm+, max over 1m) | Smaller feed size (typically under 250mm) |

| Discharge Size | Coarse (adjustable range usually 150-350mm) | Finer output (usually adjustable to 10-100mm, or even finer) |

| Crushing Ratio | Smaller (generally 3-5) | Larger (up to 10-15 mm maximum) |

| Structural Features | Wide feed opening, large movable jaw stroke | Deeper crushing chamber with increased compression cycles, ideal for fine crushing |

| Role in Production Line | Serves as the “primary crusher,” preparing material for subsequent crushing stages | Positioned after primary crushers to produce final products or feed sand makers |

We often liken primary jaw crushers to “big eaters,” tasked with breaking massive rocks into medium-sized chunks.

The fine jaw crusher acts like a “master craftsman,” further reducing the coarse-crushed blocks into smaller gravel or aggregate.

Therefore, the term “jaw crusher” commonly refers to the machine used for coarse crushing. The “fine jaw crusher” specifically denotes cone crushers employed for medium and fine crushing operations, producing finer output.

A variety of models are available | Get the free price list! Impact crushers are categorized into PF impact crushers and CI impact crushers. PF Impact crusher, also called small diameter impact crusher. CI Impact C...

View detailsPhosphate Ore Dressing Production Line Process Introduction Phosphate beneficiation is a complex, multi-step process designed to separate useful minerals (such as apatite) from waste rock in phosphate ore. Flotatio...

View detailsThe role of ball mills in heavy industries like mining and cement is undeniable, and liners are critical components of the mill cylinder. When the machine frequently emits abnormal, grating friction noises, it may indicate liner wear. This not on...

View detailsIn mineral grinding operations, ball mills have long held an almost irreplaceable position. This article provides a thorough analysis of ball mills' strengths and weaknesses, comparing them with equipment such as rod mills and autogenous mills. W...

View details