Impact Crusher

518A variety of models are available | Get the free price list! Impact crushers are categorized into PF impact crushers and CI impact crushers. PF Impact crusher, also called small diameter impact crusher. CI Impact C...

View detailsSearch the whole station Hot Product Catalog

The role of ball mills in heavy industries like mining and cement is undeniable, and liners are critical components of the mill cylinder. When the machine frequently emits abnormal, grating friction noises, it may indicate liner wear. This not only causes losses from downtime but also incurs high spare part costs.

This article provides a comprehensive analysis from material selection to maintenance, ensuring your liners no longer suffer from premature failure.

Grinding media and liners are supposed to be “partners” working in tandem within the ball mill. However, an imbalance in their interaction is precisely the root cause of accelerated liner damage.

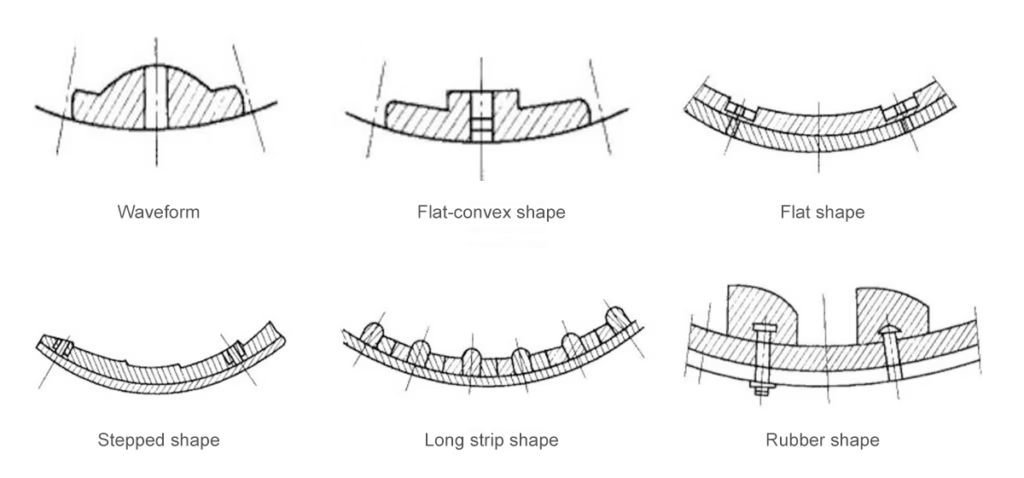

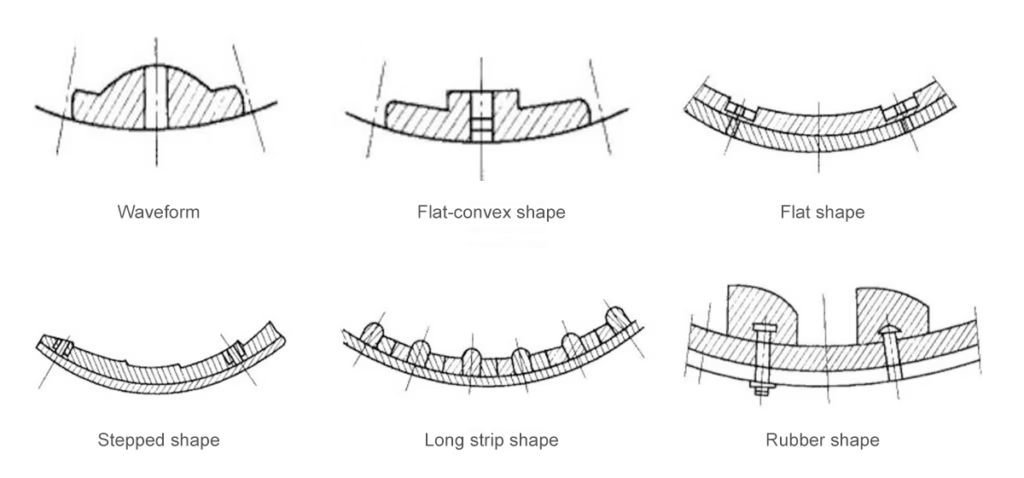

Problems arise when grinding balls are too small to match the contours of the liner’s lifting rods. These undersized balls fail to fall properly for effective grinding, instead getting lodged in the troughs between rods. This causes the balls to continuously slide and roll across the liner surface, acting like uncontrolled grinding wheels that concentrate intense wear on flat areas.

This highly destructive phenomenon, often termed “slurry splashing” or “wear shelling,” is characterized by uneven wear patterns on the liner surface: the impacted lifting rods remain largely intact, while the protected flat areas become severely worn thin. This abnormal wear pattern directly leads to a sudden drop in the overall structural strength of the liner, causing premature failure. This results in substantial waste of steel that has not yet reached its service life, significantly increasing production costs.

Optimizing the interaction between grinding media and liners is a crucial measure for minimizing liner wear.

Ideally, steel balls should have a hardness slightly lower than or equal to that of the liner plates. Excessively hard balls may cause liner cracking or deformation. Simultaneously, low-quality balls, severely worn into irregular shapes, intensify impact and cutting forces on the liners. CHUNLEI steel balls offer high wear resistance and low breakage rates, significantly reducing liner damage.

Ball mills typically operate in wet or dry grinding modes, where corrosive substances may enter. Selecting liners with superior comprehensive properties—such as low-alloy high-strength steel or high-chromium cast iron—is crucial. These materials better balance damage caused by impact and corrosion.

To prevent “ball jamming” and “slurry splashing,” the maximum steel ball diameter should not exceed 1.2 times the trough spacing between liner lift rods. This ensures balls do not get stuck in troughs and deliver proper impact force rather than sliding friction.

To achieve both coarse crushing and fine grinding, mix large, medium, and small steel balls in a 4:3:3 ratio within the mill. This effectively reduces direct contact between grinding media and liners.

You may sometimes encounter this situation: despite selecting the right steel and achieving the correct composition, wear plates still crack prematurely or exhibit reduced service life. The issue likely lies in the wear plate’s heat treatment.

Heat treatment is akin to the “heat control” in cooking. If not managed properly, it can ruin high-quality steel alloy castings, preventing the liner from achieving the required hardness and toughness while making it brittle and prone to breakage.

The core of heat treatment lies in quenching and tempering. Quenching involves controlled heating followed by rapid cooling, while tempering entails reheating and holding at a specific temperature. Do not underestimate these two steps—they determine the liner’s hardness, toughness, and wear resistance. Improper execution renders even the finest material merely ordinary metal.

Error 1: Reusing old bolts and seals may lead to frequent loosening and slurry leakage.

Error 2: Tightening directly to maximum torque in one go causes stress concentration in the liner or insufficient preload due to settling after operation.

Error 3: Adding steel shims between the liner and cylinder creates localized point contact, resulting in liner fracture and cylinder damage.

Error 4: Incorrect installation sequence or excessive gaps compromise overall liner stability, causing severe vibration and impact during operation, significantly shortening service life.

Ball mill liner wear cannot be resolved simply by replacement or production shutdowns. We trust this article has equipped you with techniques to extend liner lifespan.

True cost savings lie not in purchasing the cheapest liners, but in partnering with reliable manufacturers. CHUNLEI Machinery, with 30 years of expertise in mining machinery, offers the most professional mining knowledge, the most dependable technology, and most importantly, the best value for money. If you have any questions, please contact us immediately. We will serve you with our professional expertise!

A variety of models are available | Get the free price list! Impact crushers are categorized into PF impact crushers and CI impact crushers. PF Impact crusher, also called small diameter impact crusher. CI Impact C...

View detailsIn the mining industry, tungsten ore is known as the "teeth of industry" due to its high density and hardness. However, many mine owners face a common challenge during processing: The physical properties of Wolframite and Scheeli...

View detailsThe iron ore crushing process typically involves feeding into primary and secondary crushers, screening, fine crushing, and dry separation. For economic efficiency, finer ore fed into the dry separator generally yields a higher proportion of iron...

View detailsRefined kaolin appears as an ordinary white powder, yet it holds indispensable significance in industrial applications. Its extraction process involves a complex industrial workflow, where purity levels directly determine its value and applicatio...

View details