Rod Mill

484A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill and wet rod mill. Different from ball mill, built-in rod mill is a steel rod type grinding body, using the cen...

View detailsSearch the whole station Hot Product Catalog

Molybdenum (commonly referred to as “molybdenum”) is a critical industrial metal prized for its high strength, corrosion resistance, and heat tolerance. Though less well-known than metals like copper or gold, it is indispensable in modern industry. This guide comprehensively explores how molybdenum is extracted from the earth and transformed into usable materials that reinforce structures ranging from skyscrapers to aerospace alloys.

Molybdenum is a silvery-white metallic element that does not occur in its free state. It is primarily extracted from molybdenite ore (MoS₂), though it can also be a valuable byproduct of copper mining. The world’s major molybdenum deposits are located in the United States (Colorado), China, Chile, and Peru. The actual molybdenum content in the rock mined from these deposits is typically low, ranging from 0.01% to 0.25%. Therefore, efficient processing is crucial.

There are two primary methods for mining molybdenum, chosen based on deposit geology and depth.

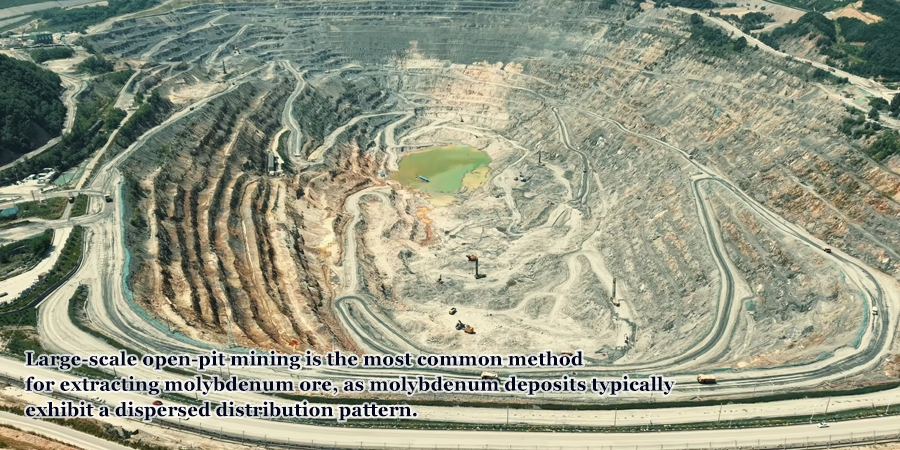

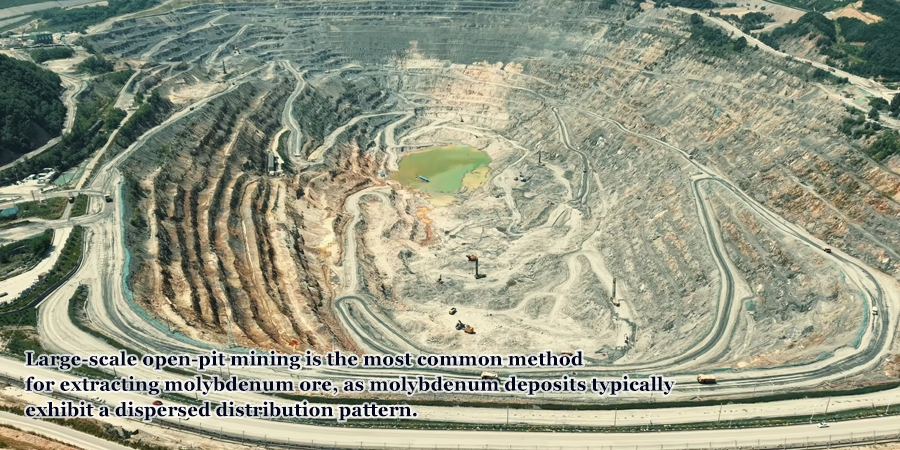

1. Open-Pit Mining (Surface Mining)

This is the most prevalent method for molybdenum extraction. When ore bodies are located relatively close to the surface, open-pit mining is the most cost-effective approach.

2. Underground Mining

When the molybdenite ore body is deep or the geological conditions are unsuitable for an open pit, underground methods are employed.

The goal of this stage is to separate the valuable molybdenite mineral from the worthless waste rock (gangue) and produce a concentrate. This process is known as froth flotation.

Step 1: Crushing and Grinding

Step 2: Froth Flotation(the heart of molybdenum recovery)

1. Conditioning: Chemical reagents are added to the slurry. These include:

2. Flotation Cells: The slurry is agitated and aerated. Hydrophobic molybdenite particles attach to air bubbles and rise to the top, forming a mineral-rich froth.

3. Skimming: The froth is skimmed off the surface. This molybdenite concentrate typically grades between 40-55% Mo.

4. Multiple Stages: The slurry passes through several cleaning and scavenging stages to maximize recovery, often exceeding 90%.

Step 3: Dewatering

The final concentrate slurry is thickened and then filtered using drum filters or press filters to create a moist filter cake (approx. 8-10% moisture) suitable for transport or roasting.

Concentrate into Molybdenum Oxide (MoO₃)

Molybdenum sulfide concentrate (MoS₂) cannot be directly used in steel alloys. The roasting process converts it into industrial-grade molybdenum oxide, known as “technical oxide.” Industrial-grade molybdenum oxide typically contains at least 57% molybdenum and less than 0.1% sulfur.

Process Flow: The concentrate is heated in a multi-chamber roaster under an oxygen-enriched atmosphere, maintaining temperatures between 600-700°C.

Output: This process releases sulfur as sulfur dioxide (SO₂), which is captured and converted into sulfuric acid in modern environmental facilities. The final product is a fine, gray MoO₃ powder.

For industries requiring ultra-high purity (e.g., chemicals or superalloys), technical oxides undergo further processing:

The processed molybdenum finds its way into countless essential products:

| Application Category | Key Properties Molybdenum Imparts | Common Products & Uses |

|---|---|---|

| Structural & Stainless Steel (~75% of total demand) | Strength, Toughness, Corrosion Resistance, Weldability | Buildings, Bridges, Pipelines, Pressure Vessels, Rebar, Architectural Cladding |

| Alloy Steels & Tool Steels | Hardenability, Strength, Wear Resistance, Thermal Hardness | Automotive Parts (crankshafts, gears), Heavy Machinery, Drills, Dies, Molds, Cutting Tools |

| Superalloys | High-Temperature Strength, Creep Resistance, Thermal Stability | Jet Engine Turbine Blades, Gas Turbines, Nuclear Reactor Components, Rocket Nozzles |

| Chemicals & Catalysts | Catalytic Activity, Thermal Stability, Lubricity | Petroleum Refining Catalysts, Lubricant Additives (moly disulfide), Corrosion Inhibitors, Pigments |

| Pure Molybdenum Metal & Alloys | High Melting Point (2,623°C), Thermal Conductivity, Low Thermal Expansion | Furnace Parts, Heat Shields, Sputtering Targets, Glass Melting Electrodes, Semiconductor Base Plates |

| Other Specialized Uses | Essential Plant Nutrient, Specialty Material Properties | Agricultural Fertilizers (for trace element deficiency), Nickel-Moly Alloys for Chemical Handling, Aerospace Coatings |

Modern molybdenum operations prioritize environmental responsibility. Key practices include:

From trace minerals sealed within granite to the core component of the world’s strongest alloys, molybdenum’s transformation is nothing short of a feat. The process encompasses three key stages—precise mining, meticulous flotation, and high-temperature treatment—ensuring efficient utilization of molybdenum.

Specific techniques and processing flows for molybdenum mining and processing may vary based on ore characteristics and environmental regulations. CHUNLEI’s expert team stands ready to customize tailored processes for you, offering one-stop services from design to equipment supply. Inquiries welcome!

A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill and wet rod mill. Different from ball mill, built-in rod mill is a steel rod type grinding body, using the cen...

View detailsAs a central grinding device, ball mills are extensively utilized in mining, construction materials, and chemical industries. However, prolonged high-load operation often leads to frequent malfunctions during practical use. This guide analyzes co...

View detailsIn the field of barite processing, have you ever faced these challenges: subpar equipment performance, inconsistent product fineness, or persistently high overall operating costs?As a cornerstone material for drilling, chemical, and coating indus...

View detailsRefined kaolin appears as an ordinary white powder, yet it holds indispensable significance in industrial applications. Its extraction process involves a complex industrial workflow, where purity levels directly determine its value and applicatio...

View details