Why do mineral processing operators prefer wet grinding ball mills for sand production?

Because the resulting sand exhibits excellent particle shape, controllable particle size, uniform output gradation, and high-quality aggregate. Wet grinding generates less dust, causes minimal pollution, and requires fewer wear parts.

What is the meaning of wet grinding?

Wet grinding, also known as wet milling or wet pulverization, is a processing technique that involves the ultrafine grinding and dispersion of solid materials in a liquid medium (typically water or organic solvents). Its core distinction from dry grinding lies in the processing environment: wet grinding occurs in liquid, while dry grinding takes place in air or vacuum.

How much water is typically added during wet ball mill operation?

The grinding slurry concentration in wet ball mills relates to slurry fluidity and viscosity. When slurry concentration decreases, increased fluidity leads to stronger impact on liners, potentially causing damage. Generally, harder or coarser ores require slightly higher slurry concentrations. In actual production, the slurry concentration for primary grinding should be controlled between 72% and 82%. This range ensures both grinding efficiency and liner service life.

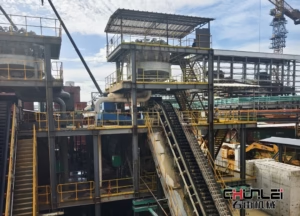

Properly controlling water addition to the ball mill reduces steel ball wear and extends mill service life. For wet grinding mills, a water addition rate of 2.5–3.0 t/h is generally optimal. The ideal crushing capacity occurs when the added water weight is slightly less than the ore weight, resulting in fines (slime) comprising 50–60% of the crushed ore. Zhengzhou Chunlei Machinery specializes in mining equipment production, with experienced technicians who select suitable equipment models based on your processing plant characteristics and budget. For further inquiries, please contact us anytime. We will promptly provide customized solutions.”

What are the advantages of wet grinding?

From an overall economic perspective, wet grinding is generally adopted in mineral processing production lines. This is because ball mill wet grinding offers the following benefits:

1. Lower energy consumption per ton of product and higher processing capacity per unit volume.

2. No dust issues associated with wet grinding in ball mills.

3. Higher processing capacity per unit volume in wet ball mills.

4. Ability to strictly control final product particle size using classifiers or wet screening equipment.

5. Simplified material handling via pumps, pipelines, and chutes.

What is the function of a wet grinder?

Wet grinding technology is an indispensable process in many high-end manufacturing industries. Below are the primary functions of wet grinding:

- Ultra-fine grinding and particle size reduction

This is the most direct function of wet grinding. It can reduce solid particle sizes from millimeter and micrometer scales down to micrometers, submicrometers, or even nanometers.

- Uniform Dispersion and Mixing

Wet grinding efficiently blends multiple solid components (such as pigments, fillers, and active substances) within a liquid medium while preventing particle re-agglomeration.

- Morphological Modification and Surface Activation

During pulverization, high-speed mechanical forces create surface defects on particles, increasing their surface energy and reactivity.

- Safety Assurance

The wet grinding process occurs entirely within a liquid medium, fundamentally eliminating the risk of dust explosions and preventing health hazards from harmful dust inhalation for operators.

Ball mill wet grinding is suitable for most common materials, including quartz ore, tungsten ore, copper ore, iron ore, tantalum-niobium ore, lead-zinc ore, and others. Any material that does not react with water and does not adversely affect product quality can be processed via wet grinding.