Blast furnace slag is an industrial byproduct generated during the ironmaking process in blast furnaces. When smelting pig iron, iron ore reacts at high temperatures with coke, limestone, and other flux agents within the furnace. Impurities in the ore combine with the flux agents to form a lighter-density material—this is blast furnace slag. GGBS grinding plants transform blast furnace slag into high-performance admixtures that enhance concrete durability while reducing carbon emissions, making it a vital material for the cement and concrete industries.

Process Flow: The Transformation Journey from Waste Slag to Micropowder

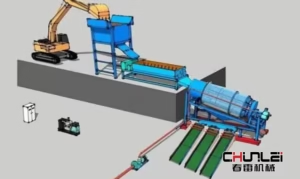

The blast furnace slag grinding plant operates as a highly integrated system where each stage works in close coordination. This creates a closed-loop, efficient, and environmentally friendly production process that converts raw materials into high-value-added slag micropowder.

1.Material Pre-treatment

Molten slag discharged from blast furnaces undergoes water treatment to form granulated blast furnace slag. Iron impurities are removed via magnetic separation, followed by primary crushing to a particle size <50mm before proceeding to the next stage.

2.Grinding and Classification

After drying, the slag enters grinding equipment for pulverization. Vertical mills suit large-scale continuous production, while ball mills are used for applications requiring extremely fine particle sizes. Finished product fineness is graded, with non-compliant particles returned to the grinding chamber for reprocessing.

3.Dust Removal and Collection

Dust is collected using pulse-jet baghouse dust collectors and wet dust collection systems to meet environmental standards. Qualified slag microsilica is transported to the finished product silo via pneumatic conveying chutes and bucket elevators.

Core Equipment of High-Efficiency Grinding Systems

Ball Mill

Ball mills remain dominant in slag grinding plants due to their stable product particle size and ability to process ultra-fine products. They are commonly paired with high-efficiency dynamic classifiers.

- Working Principle: Slag collides and grinds against steel balls within a rotating cylinder. After discharge, the material undergoes classification via the classifier, separating fine powder from coarse particles.

- Core Advantages: Mature equipment, simple maintenance, and excellent product uniformity make it suitable for specialty cement production with stringent particle size distribution requirements.

- Optimization Directions: Significantly enhance system efficiency by increasing grinding chamber length, optimizing steel ball grading, and incorporating roller press pre-grinding.

Vertical Roller Mill

The vertical roller mill is the most widely used grinding equipment in blast furnace slag grinding plants, integrating drying, grinding, and classification functions.

- Working Principle: Slag is crushed by high-pressure rollers on the grinding disc while hot air is blown in from the bottom, achieving simultaneous drying and grinding. Fine powder is carried by airflow to the top classifier for separation, while coarse powder returns for re-grinding.

- Core Advantages: 30%-40% lower energy consumption than traditional ball mills, quiet operation, compact footprint, suitable for large-scale continuous production.

- Applications: Widely used in large-scale slag micropowder production lines with annual capacities exceeding 300,000 tons.

Ultrafine Vertical Mill + Ball Mill

This combination is essential for producing high-end products, offering lower energy consumption and superior control over product fineness. Ideal for high-performance concrete and specialty engineering materials.

Conclusion

Whether seeking the optimal solution to reduce the overall cost of concrete or maximizing the value of slag powder, the key lies in finding a partner whose quality and service are truly trustworthy.

With years of industry expertise, CHUNLEI Machinery offers comprehensive solutions focused on “cost reduction, efficiency enhancement, and operational stability.” We have successfully served hundreds of clients worldwide. If you share these objectives, contact us anytime. We will leverage our professional knowledge and technology to tailor the most cost-effective production line and provide complete equipment solutions for your needs. Contact us today!