Search the whole station Hot Product Catalog

CHUNLEI Machinery specializes in gravity, magnetic, and flotation separation technologies, efficiently extracting high-grade concentrates from raw ore by recovering precious metals such as gold and copper.

CHUNLEI Machinery’s mineral processing equipment handles various materials including ferrous metal ores, non-ferrous metal ores, non-metallic minerals, and other materials.

Additionally, materials such as cement, ceramics, coal, fertilizers, and refractory materials can also be processed.

Before mining and processing minerals, we provide complimentary production line design to help you rapidly establish your project and maximize profitability.

With 30 years of industry experience, CHUNLEI Machinery provides customized mineral processing solutions and complete equipment sets, including spare parts and after-sales service. Our team of mineral experts assists you in precisely selecting the right processing equipment to achieve maximum economic benefits at the lowest cost.

All CHUNLEI mineral processing equipment is designed and manufactured in our own factory, giving us an absolute advantage in pricing. Simply tell us your requirements, and we’ll provide a complete production line design along with the most cost-effective full set of equipment.

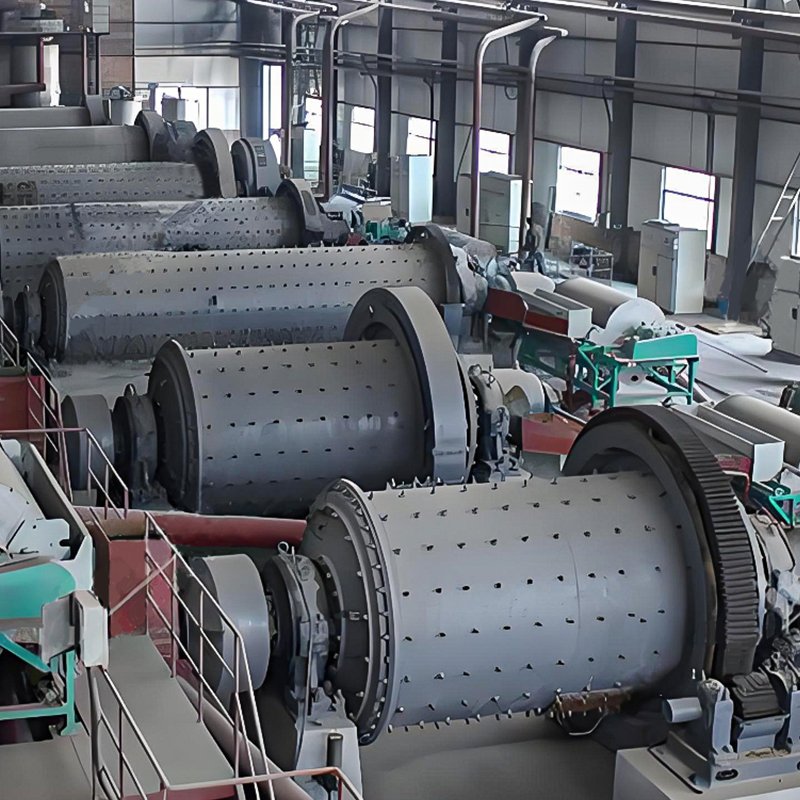

After crushing, you can choose our mineral processing equipment, which covers the entire process including grinding, classification, gravity separation, flotation, and dewatering. Each set undergoes rigorous quality control before leaving our factory, ensuring efficient operation, minimal downtime, and maximum service life.

Gold Ore Gravity Separation Production Line Process Introduction Gold ore re-selection is a complex and multi-step process involving crushing, screening, desludging, re-selection, classification, combined process and tailings treatment. The recovery rate and economic benefits of gold ore can be effectively improved through reason…

Gold Mine CIP – Carbon in pulp Process CIP Introduction Gold CIP (Carbon in Pulp) is a non-filtered cyanide carbon slurry process that recovers gold from cyanide slurry through activated carbon adsorption. Gold CIP is the ideal choice for processing oxidized gold ores with low sulfur content and high clay content. CHUNLEI is a …

Gold Flotation Production Line Process Introduction Gold flotation production line is a production line used for gold ore dressing, which is often used to process sulfide mineral gold-containing ores with high floatability. Gold minerals are mainly separated from ores through flotation process. The cost of mineral processing is l…

Steel Slag Processing Production Line Though steel slag appears to be low-cost waste material, crushed and purified slag boasts high iron content, soaring prices, and significant market demand. Processed steel slag can be utilized as a smelting flux aid, cement raw material, construction aggregate, road aggregate, brick material, slag f…

Phosphate Ore Dressing Production Line Process Introduction Phosphate beneficiation is a complex, multi-step process designed to separate useful minerals (such as apatite) from waste rock in phosphate ore. Flotation: Flotation is one of the main methods in phosphate beneficiation. It is suitable for processing ph…

Graphite Ore Dressing Production Line Process Introduction Crystalline graphite has natural floatability, so flotation is mainly used to separate graphite ore. For graphite ore with multiple gangues, gravity separation and flotation combined process can also be used. Ishiguro ore dressing production line usually …

Fluorite Ore Dressing Production Line Process Introduction Fluorite ore beneficiation methods include gravity separation and flotation, which are also divided into gravity separation equipment and flotation equipment. Gravity separation equipment refers to jigs, and only jigs can process coarse-grained fluorite lumps. Fluorite fl…

Quartz Sand Dressing Production Line Process Introduction The quartz sand beneficiation process is mainly for purification, removing small or trace amounts of impurities in quartz sand to obtain refined quartz sand or high-purity quartz sand, which is a highly difficult separation technology. The quartz sand purification processe…

Feldspar Ore Dressing Production Line Process Introduction According to different types of feldspar minerals and ore properties, Chunlei has developed a series of different feldspar ore dressing processes, including magnetic separation, flotation, gravity separation or combined processes, so as to remove mica mineral impurities a…

Kaolin Dressing Production Line Process Introduction Wet and dry separation are the two main processes of the Spring Thunder kaolin beneficiation process.The dry separation process is used to process kaolin ores with high whiteness and low gravel content;The wet kaolin beneficiation process is used to process complex kaolin ores…

Dolomite Dressing Production Line Process Introduction Dolomite beneficiation process is a beneficiation solution to separate dolomite concentrate from dolomite ore. Based on the mosaic structure of dolomite ore and years of beneficiation process experience, Chunlei beneficiation process adopts two-stage crushing, washing, three-…

Chunlei Machinery started in 1990 and registered Chunlei Machinery in 2017, which is the first choice for domestic and overseas customers to import mining machinery and equipment from China.

Enhance the service consciousness, strengthen the professional skills training, to create a standardized, professional, elite high-quality team, for the user to solve problems.

Our company mainly produces five series of products: crusher, sand making equipment, mineral processing machinery, gold processing machinery, dryer, rotary kiln, cement production line, concrete mixing plant. At the same time, the company provides customers with project design, process design, standard and non-standard product design and production.

A variety of models are available | Get the free price list! Spiral sand washing machine is a kind of sand washing machine. It is used with sand making machine and plays an important role in sand ma…

A variety of models are available | Get the free price list! High gradient magnetic separator is a new type of strong magnetic separator developed on the basis of general strong magnetic separator, whose magnetic …

A variety of models are available | Get the free price list! Hydrocyclone (centrifugal de-selector) is a kind of high-efficiency classifying and de-sludging equipment for fine-grained materials, which is mainly us…

A variety of models are available | Get the free price list! Sinking spiral classifier is a kind of equipment that utilizes the difference of settling speed of solid particles in liquid to carry out mechanical cla…

A variety of models are available | Get the free price list! High weir spiral classifier is a kind of equipment used to classify solid particles in the slurry, and its main feature is to utilize the difference of …

A variety of models are available | Get the free price list! The Concentrator, also called high-efficiency thickener, is a gold mining equipment used for the separation of gold leach solution Guye. It adopts a brand-…

A variety of models are available | Get the free price list! Agitation tanks are also called leaching agitation tanks or Stirring Tanks. According to the different structure of the agitation tank, it can be divided i…

A variety of models are available | Get the free price list! Wet magnetic separator is also called wet permanent magnetic separator, the magnetic system material selection of high performance, high coercivity, high r…

loading…

This is the last article!

Ceramic ball mills are grinding equipment that replaces traditional metal liners with ceramic liners and uses ceramic balls (such as alumina, zirconia, silicon carbide, etc.) as grinding media. Material is finely p…

A variety of models are available | Get the free price list! Wet pan mill, also known as gold ore grinding mill,Wet discs mill, consists of rollers and discs as the main working parts. It is named after the diamete…

A variety of models are available | Get the free price list! Raymond mill is also called ultrafine grinding equipment, adopts a number of patented technologies such as bevel gear integral drive, internal thin oil …

A variety of models are available | Get the free price list! The autogenous mill, also called ultrafine laminar autogenous mill/semi-autogenous mill, is a new type of autogenous mill, which is a kind of grinding e…

A variety of models are available | Get the free price list! Firstly, let’s introduce the main ore processed by gold separating ball mill – gold ore.Gold ore is the ore that contains gold elements or gold compounds. …

A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill and wet rod mill. Different from ball mill, built-in rod mill is a steel rod type grinding body, using the cen…

loading…

This is the last article!

Centrifugal concentrators,also known as a mineral processing centrifuge, represent a pivotal advancement in mineral processing, utilizing high G-force fields to achieve superior density-based separation. These machines excel at capturing fine, heavy mineral particles—particularly those smaller than 0.074mm (200 mesh)—that are frequently lost …

The global graphite market is undergoing a dramatic transformation, driven primarily by the exponential growth of the electric vehicle (EV) battery sector. A graphite mine’s profitability in 2026 is no longer determined by carbon grade alone, but critically by its ability to preserve large crystalline flakes throughout the entire processing cir…

Oxidized gold ore, often found near the surface where weathering has altered its chemical composition, presents both a challenge and an opportunity for miners and prospectors. Unlike refractory sulfide ores, oxidized ore is typically more porous and amenable to conventional extraction methods, often yielding higher recovery rates. This guide wi…

Sand is one of the most fundamental materials in construction, manufacturing, and industry. Yet its properties—particularly its density—vary dramatically based on particle size, composition, and moisture content. Understanding these variations isn’t just academic; it’s essential for calculating material requirements, ensuring structural integri…

We would appreciate it if your message contains the required equipment, the type of project, the export country, and the budget amount so that you can get the most accurate quote!

Contact Us

If you need to know more product information

Submit your product intentions and needs, we will contact you in the first time!