Rod Mill

498A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill and wet rod mill. Different from ball mill, built-in rod mill is a steel rod type grinding body, using the cen...

View detailsSearch the whole station Hot Product Catalog

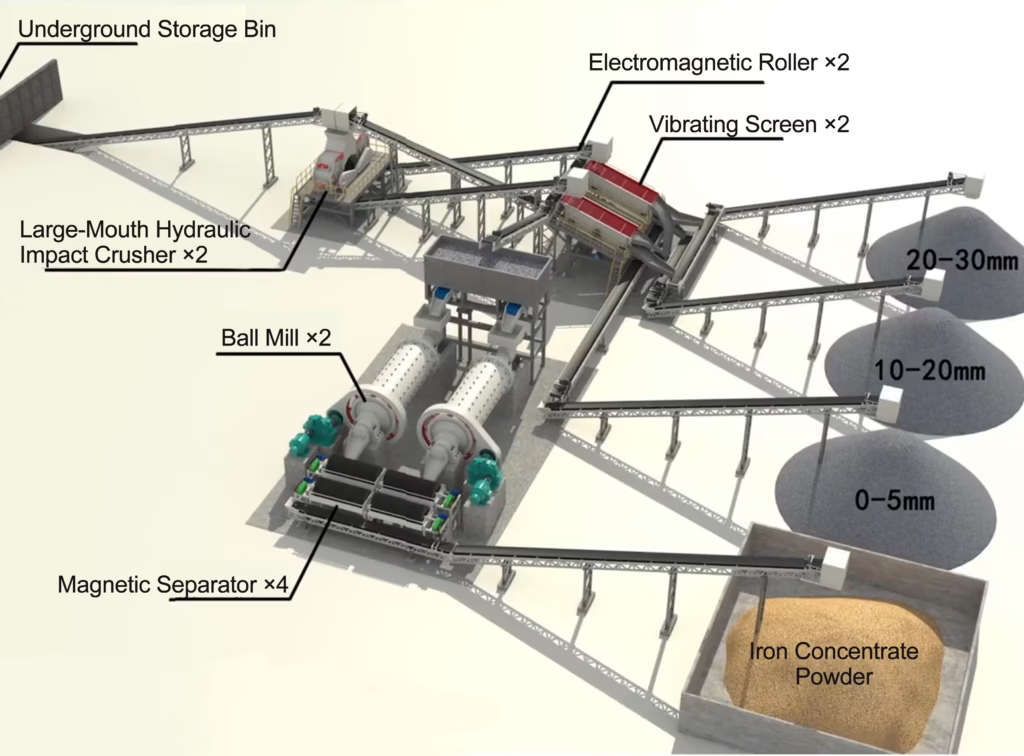

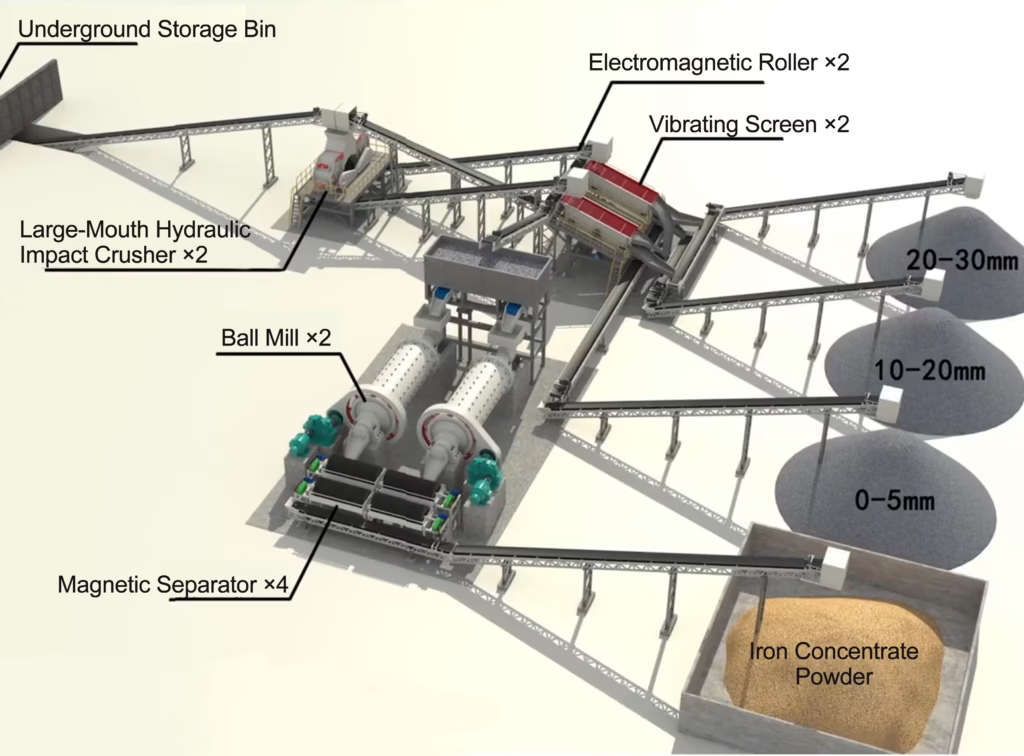

The iron ore crushing process typically involves feeding into primary and secondary crushers, screening, fine crushing, and dry separation. For economic efficiency, finer ore fed into the dry separator generally yields a higher proportion of iron-bearing ore recovered. Some small processing plants directly subject iron ore crushed by fine jaw crushers to dry separation, resulting in severe waste of natural resources.

The crushing stage involves breaking down the iron ore. Due to the high hardness of iron ore, specific requirements exist for crushing equipment selection. Large iron ore chunks are uniformly fed by a vibrating feeder into a jaw crusher for primary crushing. Material of suitable size is then sent to a cone crusher for secondary crushing, achieving a final particle size of 0-12mm.

In iron ore production, primary crushing typically employs a jaw crusher. As the most traditional and stable primary crushing equipment, jaw crushers offer the widest range of applications. For secondary crushing in iron ore processing, two types are commonly selected: either a fine jaw crusher or a cone crusher. From the perspective of iron ore production efficiency and cost, employing cone crushers can effectively reduce production expenses.

During the screening stage, material that does not meet the required particle size after passing through a vibrating screen is sent back to the cone crusher for further crushing. Iron ore that meets the required particle size is then conveyed to the next grinding process.

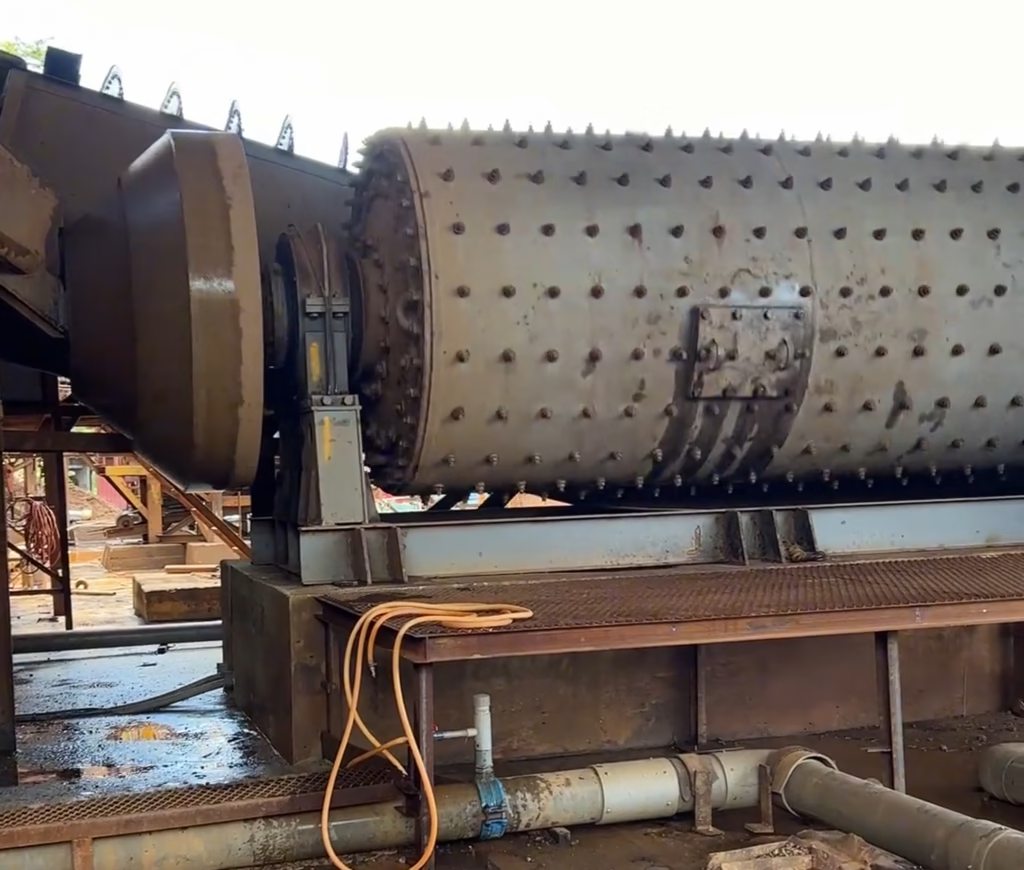

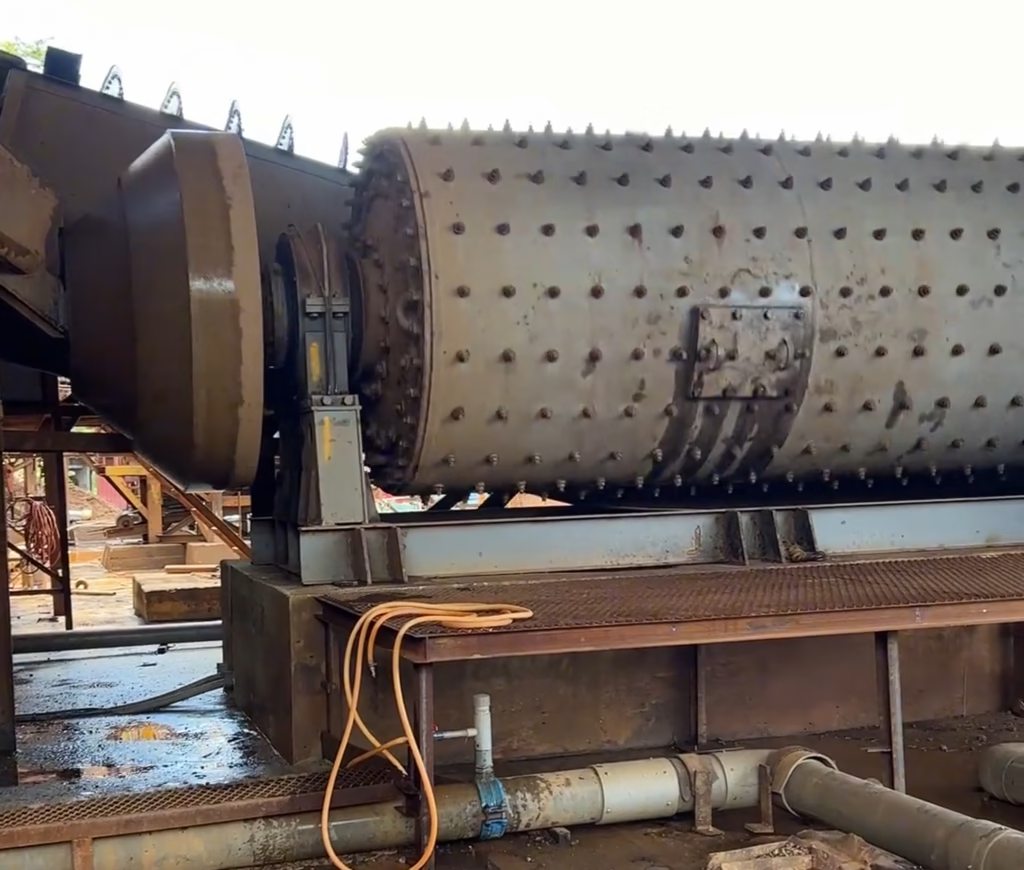

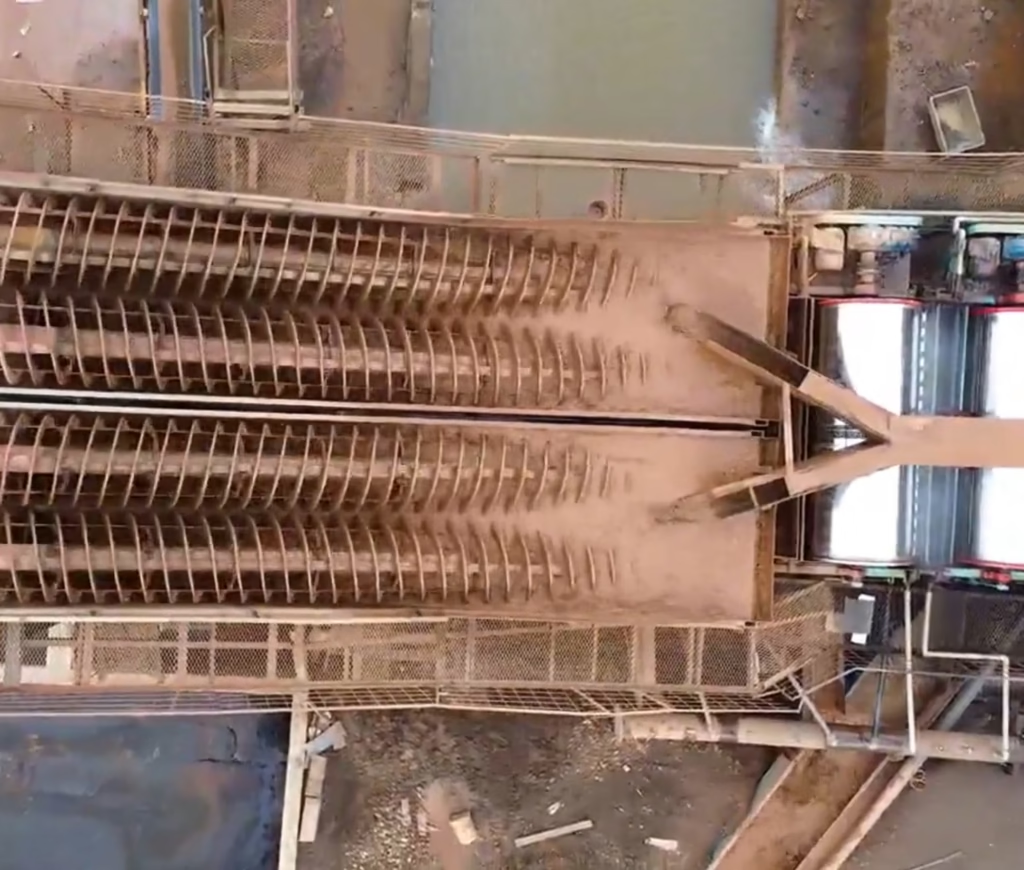

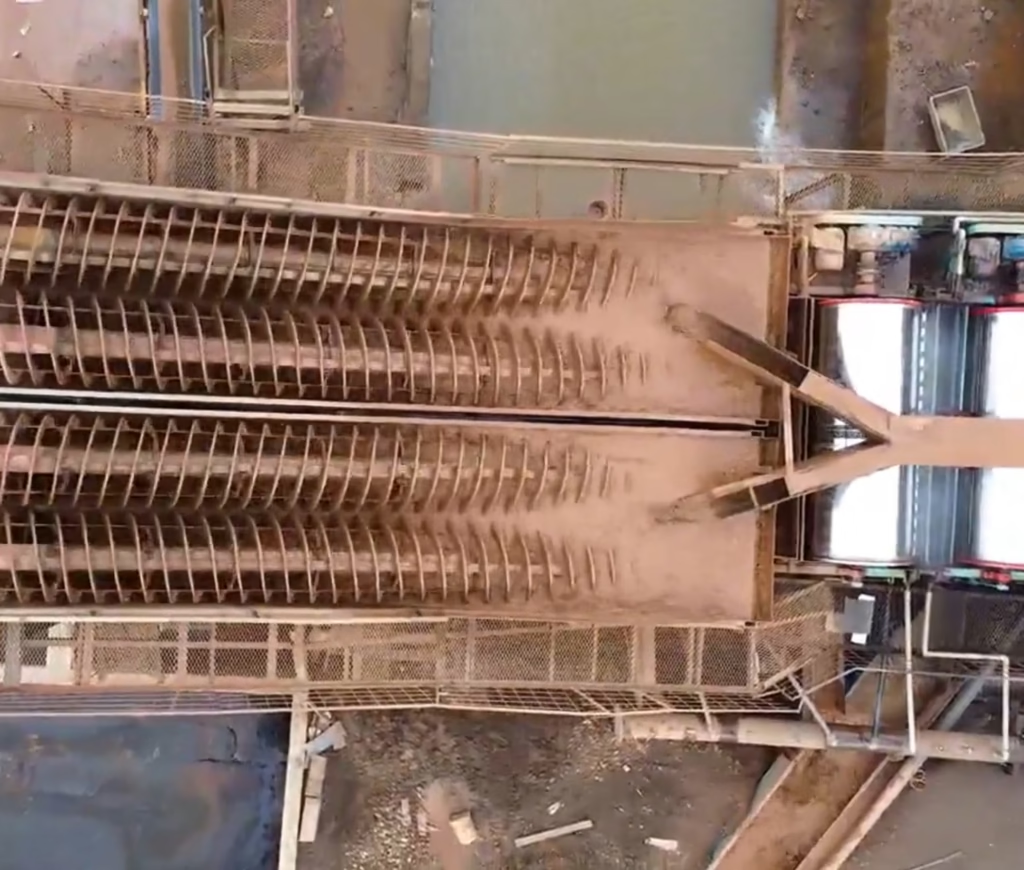

The beneficiation stage begins with grinding, primarily reducing iron ore to powder form. Ball mills are predominantly chosen for iron ore grinding. Material from the primary crushing stage is uniformly fed into the ball mill for pulverization. A spiral classifier then discharges material meeting specifications for subsequent beneficiation operations, while undersized material is returned to the ball mill for further grinding. Qualified material must undergo impurity removal. Magnetic separators effectively eliminate contaminants, ensuring low-grade ore is transformed into high-grade raw material meeting smelting requirements.

In summary, iron ore beneficiation is a complex and precise industrial process with the core objective of “increasing iron content while reducing impurities.” Transforming bulk ore into qualified iron concentrate involves crushing and screening to achieve appropriate particle size, grinding to ensure complete liberation, followed by core separation techniques like magnetic separation or flotation to isolate iron minerals from gangue. The final product is obtained through dewatering. This process transcends mere physical separation; it embodies comprehensive technological proficiency in resource efficiency, energy consumption control, and environmental protection, serving as an indispensable link between mining and the steel industry.

A variety of models are available | Get the free price list! Rod mill can be divided into dry rod mill and wet rod mill. Different from ball mill, built-in rod mill is a steel rod type grinding body, using the cen...

View detailsIn the gold extraction process, carbon in leach (CIL) and carbon in pulp (CIP) have become the mainstream extraction technologies. In this article, we will deeply analyze the core advantages, working principle and purchase guide of CIL/CIP gold l...

View detailsMica Dressing Production Line Process Introduction Mica beneficiation production line is a set of efficient and environmentally friendly process and equipment combination, which can not only extract high purity mica minerals, but a...

View detailsZinc Ore Beneficiation Process Process Introduction The core of zinc ore beneficiation technology is flotation, which realizes the effective recovery and grade improvement of zinc minerals through the steps of pretreatment, roughin...

View details