In mineral processing, if any piece of equipment plays an indispensable role, it is undoubtedly the ball mill. It has always been the irreplaceable “heart” of the process. As one of the most crucial grinding devices, the ball mill features a simple structure and can grind a wide variety of materials. It serves as the vital bridge connecting resource extraction to the transformation into high-value products.

Core Principle of Ball Mills:

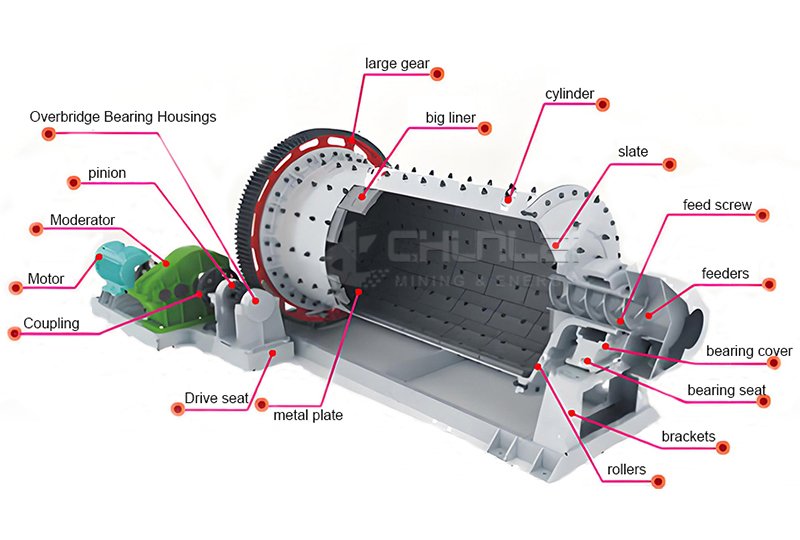

Despite its simple structure, the ball mill embodies the essence of grinding power—a classic fusion of mechanics and technology. It primarily consists of a cylinder, feeding section, discharging section, transmission system, and rotating components. The main body is a large, horizontally positioned cylinder capable of rotating around its axis, internally loaded with a specific proportion of grinding media (such as steel balls or ceramic balls).

The mill cylinder is typically crafted from high-grade steel, offering excellent strength and wear resistance to withstand immense pressure and impact forces during grinding. Depending on process requirements, the cylinder can feature a single-compartment or multi-compartment design. Single-compartment ball mills, with their straightforward structure, are suitable for coarse grinding operations; while multi-compartment mills use partition plates to divide the cylinder into multiple grinding chambers. Different chambers can hold grinding media of varying sizes and materials, enabling graded grinding of materials to enhance grinding efficiency and product quality.

Driven by an electric motor, the cylinder rotates, lifting the grinding media to a certain height before releasing them. During this process, the material primarily experiences three forces:

- Impact Crushing: The primary and most efficient coarse crushing force. As the mill rotates, grinding media (steel balls, etc.) are elevated and then released, colliding with material chunks at high kinetic energy to cause brittle fracture and fragmentation.

- Grinding and Abrasion: The core force for achieving fine grinding. As the grinding media layer slides and rolls, the material undergoes shear forces between balls and between balls and liners. This action “peels” the material layer by layer into finer, more uniform particles.

- Friction Crushing: This is the primary force for achieving fine particles. Already smaller particles are subjected to mutual compression, friction, and kneading within the gaps between media, further refining them. However, this process is slow and energy-intensive; improper timing may lead to “over-grinding.”

These three forces are not isolated but controlled through parameters like rotational speed, media ratio, and filling rate. Impact is intensified for coarse crushing, while grinding is prioritized for fine grinding with reduced excessive friction, maximizing resource value.

Core Advantages: Why It Is an Irreplaceable Cornerstone Equipment

- High Adaptability: From diamond ore with extremely high Mohs hardness to soft talc, from metallic minerals to chemical raw materials, ball mills can process nearly all solid materials.

- Controllable Particle Size: A single unit achieves ultra-high grinding ratios (up to 300+) from feed sizes of tens of millimeters to finished products of micrometers. By forming closed-circuit circuits with classification equipment (e.g., spiral classifiers, hydrocyclones, air classifiers), it precisely controls final product fineness.

- Versatile process adaptability: Capable of both wet grinding (slurry-based) to prevent dust and facilitate subsequent flotation, and dry grinding to eliminate drying steps, meeting demands in industries like building materials.

- High production capacity: Ideal for large-scale, continuous industrial operations, serving as the core equipment in modern mineral processing plants and powder processing facilities.

Conclusion

As the core equipment in industrial grinding, ball mills’ price, quality, and performance are paramount concerns for buyers. For decades, CHUNLEI Machinery has specialized in developing and manufacturing high-end grinding and classification equipment. We not only deliver premium machinery but also provide end-to-end solutions encompassing design planning and after-sales support. If you face grinding challenges, feel free to contact us anytime. We’ll leverage our expertise to help you “grind” your way to success.